Product Details

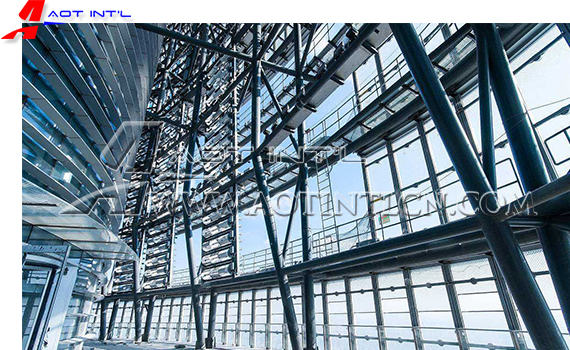

Tall Steel Frame Building | Steel High-rise Structures

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

As experts on Pre-engineered steel structure building, Prefabricated house and Modular container house system, AOT is providing complete customized solutions including consulting, R&D, design, manufacture, installation, supervision service for overseas project, export and service.

We specialize in creation of high-quality Pre-engineered steel structure building such as: warehouse, workshop, factory, cold storage, high-rise building, shopping mall, power plants, distribution centers, pedestrian bridge, hotels, public schools, sports arenas, car parking center, airplane hangars, church building, farm building, agricultural building, storage shed, self-storage building, poultry farm and green house; Prefabricated house and Modular Container house such as: portable cabin, labor camp, labor quarter, worker dormitory, construction site office, accommodation, recreation, clinic, medical facilities, quick-assemble container, sanitary container, toilet container, shower container, canteen, portable living units, portable office. We provide our time-tested PEBs, Prefabricated house and Modular container house to clients in the sectors of oil & gas, mining, Energy, Infrastructure and Construction projects. AOT built his reputation upon Profession, Reliability and Service.

Headquartered in Qingdao, China, supported by our dedicated teams with more than 10years extensive knowledge of Pre-engineered steel structure building, Prefabricated house and Modular container house, AOT has carried out 100+ projects in more than 30 countries. With the brand-building concept, AOT has built long lasting partnerships with different private international companies as well as organizations & government.

VISION, MISSION & VALUES

VISION

ALWAYS ON TOP!

MISSION

Bring our successful experience of over 10years and high quality products and service to customers;

Build our winning formula upon how well we satisfy customers’ needs, the only reason for we exist is to serve customers;

Believe our employees are our most valuable resource, Teamwork, working to make those around us better.

VALUES

Profession

Reliability

Service

WHAT MAKES AOT DIFFERENT

Profession. Profession is the cornerstone for AOT, our Pre-engineered steel structure building, Prefabricated house and Modular container house are customized design to fit your exact needs. AOT have extensive knowledge of PEBs, Prefab and container house system to ensure customers receive the highest quality buildings and very best solutions in the market.

Reliability. Reliability is the key for AOT, therefore, AOT devote countless hours to understanding each project and is committed to design/fabricate in accordance with highest international standards like ISO9001 etc. We ensure that each project is cost-effective, efficient and built with the right steel in mind.

Service. Service is core for AOT, the only reason for we exist is to serve customers. Experienced management, Strong bonding capacity, Dedicated engineers, Advanced quality control and inspection system, Complete consulting-assist from schematics to installation, all those ensure us to improve our products and services to meet the evolving construction market demands.

TESTIMONIALS

" The whole experience working with AOT INT'L was pleasure. They are professionals and experienced, the site supervisor is quite good too, the whole constructions took only 3month. This is the second steel structure warehouse projects I dealing with AOT INT'L, I trust them for all my steel structure buildings needs. "

--- Amir M, Maldives

“ The team of AOT is excellent, their know-how helps me a lot, cause all my Flat pack container house projects are special and total customized. I am glad that I worked with AOT since years of 2016, we will look for long-terms co-operations”

---Антон, Russia

“ It is a such pleasant experience with AOT teams, they are masters in the Prefab house market, they provide all the proposal design for my worker quarters prefab house, and they know how to make the balance between quality and cost. Cause even the prefab house seems very simple, but there were some many different specifications, they well know which type will be suitable for my site. I highly recommend them for everyone looking for a solid, dependable Prefabricated building.”

--- FRANCISCO II, Philippines

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer's requirements.

Pre-engineered steel buildings are used for diverse applications such as:

Warehouse; High-rise building /Multi floor building; Prefabricated schools /Classrooms; Workshop; Shopping mall; Sports arenas & sports hall; Factory /Plant; Distribution centers /Showrooms; Church building; Cold storage building; Steel structure hotels; Steel structure hospital; Power plants; Car parking center; Steel frame pedestrian bridge; Airplane hangars & aviation hangars; Poultry farm; Garage; Storage shed; Agricultural building & barns; Community center; Self-storage building; Green house;

Tall Steel Frame Building | Steel High-rise Structures: |

| AOT Steel Structure Building | AOT Multi-Storey Steel-framed Commercial Office Building |

| |

| AOT Steel Structure Building | AOT High-rise steel structures |

The high-rise building is generally defined as one that is taller than the maximum height which people are willing to walk up; it thus requires mechanical vertical transportation. This includes a rather limited range of building uses, primarily residential apartments, hotels, and office buildings, though occasionally including retail and educational facilities. A type that has appeared recently is the mixed-use building, which contains varying amounts of residential, office, hotel, or commercial space. High-rise buildings are among the largest buildings built, and their unit costs are relatively high; their commercial and office functions require a high degree of flexibility.

| AOT Steel Structure Building | AOT Frame Steel Structure Multi Storey Pre Engineered Steel Buildings |  |

| |

| AOT Steel Structure Building | AOT Tall Steel Frame Building Steel Highrise Structures |

Classification of structural systems

The types of structures used for high-rise buildings must meet the lateral load performance criteria outlined above, and they must be reasonably efficient in the use of material and of reasonable cost. The most efficient high-rise structure would meet the lateral load criteria using no more material than would be required for carrying the building gravity load alone; in other words, it would have no premium for height. This economic criterion of “no premium for height” has led to a classification of high-rise structures, each of which has only a small premium for a particular range of height (Figure 2).

High-rise structures begin at the lowest range with the rigid frame in both steel and concrete. Some or all of the joints between the beams and columns are rigidly joined together by welding the steel or pouring the concrete in situ, and lateral resistance is provided by the rigid joints; this system can rise about 90 metres (300 feet) with little premium. The next type is the rigid frame with a vertical shear truss in steel or a shear wall in concrete to provide greater lateral rigidity; it has a range of 38 to 150 metres (125 to 500 feet). The framed tube structure in both steel and concrete brings more gravity load and more structural material to closely spaced columns at the building’s perimeter, again increasing lateral rigidity; this type is reasonably efficient from 38 to 300 metres (125 to 1,000 feet) in height. The trussed tube with interior columns, which can also be executed in both steel and concrete, introduces diagonal bracing on all sides of the building’s perimeter. The bracing also carries gravity loads and further raises the lateral rigidity, making this a low-premium structure for the region of 240 to 360 metres (800 to 1,200 feet). The bundled tube, which consists of a number of framed tubes joined together for even greater lateral rigidity, begins to be practical at about 75 metres (250 feet). It was the form of the steel structure used for the Sears (now Willis) Tower in Chicago. Beyond this height there is another system that appears to have a low premium: the superframe. In this structure much of the building’s gravity load, and therefore its material, is brought to a diagonally braced superframe tube at the perimeter by interior transfer trusses of various configurations. No true superframes have yet been built.

| AOT Steel Structure Building | AOT Multi floor steel structure complex building |

| |

| AOT Steel Structure Building | AOT Steel Structure Office Building |

Types of High-Rise Buildings Structural Systems

1. Braced frame structural system

2. Rigid frame structural system

3. Wall-frame system (dual system)

4. Shear wall system

5. Core and outrigger structural system

6. Infilled frame structural system

7. Flat plate and flat slab structural system

8. Tube structural system

9. Coupled wall system

10. Hybrid structural system