Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer's requirements.

Pre-engineered steel buildings are used for diverse applications such as:

| Industry: | Commercial: | Public: |

| ★ Warehouse; | ★ High-rise building /Multi floor building; | ★ Prefabricated schools /Classrooms; |

| ★ Workshop; | ★ Shopping mall; | ★ Sports arenas & sports hall; |

| ★ Factory /Plant; | ★ Distribution centers /Showrooms; | ★ Church building; |

| ★ Cold storage building; | ★ Steel structure hotels; | ★ Steel structure hospital; |

| ★ Power plants; | ★ Car parking center; | ★ Steel frame pedestrian bridge; |

| ★ Airplane hangars & aviation hangars; | ★ Poultry farm; | ★ Garage; |

| ★ Storage shed; | ★ Agricultural building & barns; | ★ Community center; |

| ★ Self-storage building; | ★ Green house; |

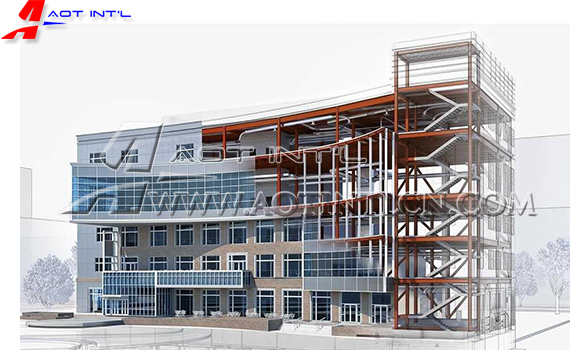

Structural Steel Framing High-Rise | Multi Storey | Mid-Rise Commercial Steel Building: |

| AOT Steel Structure Building | AOT Multi-Storey Steel-framed Commercial Office Building |

| |

| AOT Steel Structure Building | AOT High-rise steel structures |

The high-rise building is generally defined as one that is taller than the maximum height which people are willing to walk up; it thus requires mechanical vertical transportation. This includes a rather limited range of building uses, primarily residential apartments, hotels, and office buildings, though occasionally including retail and educational facilities. A type that has appeared recently is the mixed-use building, which contains varying amounts of residential, office, hotel, or commercial space. High-rise buildings are among the largest buildings built, and their unit costs are relatively high; their commercial and office functions require a high degree of flexibility.

| AOT Steel Structure Building | AOT Frame Steel Structure Multi Storey Pre Engineered Steel Buildings |  |

| |

| AOT Steel Structure Building | AOT Tall Steel Frame Building Steel Highrise Structures |

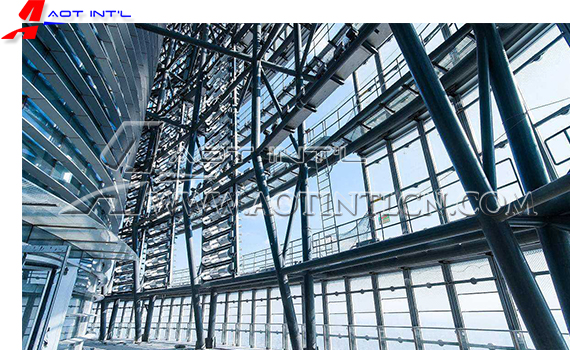

Classification of structural systems

The types of structures used for high-rise buildings must meet the lateral load performance criteria outlined above, and they must be reasonably efficient in the use of material and of reasonable cost. The most efficient high-rise structure would meet the lateral load criteria using no more material than would be required for carrying the building gravity load alone; in other words, it would have no premium for height. This economic criterion of “no premium for height” has led to a classification of high-rise structures, each of which has only a small premium for a particular range of height (Figure 2).

High-rise structures begin at the lowest range with the rigid frame in both steel and concrete. Some or all of the joints between the beams and columns are rigidly joined together by welding the steel or pouring the concrete in situ, and lateral resistance is provided by the rigid joints; this system can rise about 90 metres (300 feet) with little premium. The next type is the rigid frame with a vertical shear truss in steel or a shear wall in concrete to provide greater lateral rigidity; it has a range of 38 to 150 metres (125 to 500 feet). The framed tube structure in both steel and concrete brings more gravity load and more structural material to closely spaced columns at the building’s perimeter, again increasing lateral rigidity; this type is reasonably efficient from 38 to 300 metres (125 to 1,000 feet) in height. The trussed tube with interior columns, which can also be executed in both steel and concrete, introduces diagonal bracing on all sides of the building’s perimeter. The bracing also carries gravity loads and further raises the lateral rigidity, making this a low-premium structure for the region of 240 to 360 metres (800 to 1,200 feet). The bundled tube, which consists of a number of framed tubes joined together for even greater lateral rigidity, begins to be practical at about 75 metres (250 feet). It was the form of the steel structure used for the Sears (now Willis) Tower in Chicago. Beyond this height there is another system that appears to have a low premium: the superframe. In this structure much of the building’s gravity load, and therefore its material, is brought to a diagonally braced superframe tube at the perimeter by interior transfer trusses of various configurations. No true superframes have yet been built.

| AOT Steel Structure Building | AOT Multi floor steel structure complex building |

| |

| AOT Steel Structure Building | AOT Steel Structure Office Building |

Types of High-Rise Buildings Structural Systems

1. Braced frame structural system

2. Rigid frame structural system

3. Wall-frame system (dual system)

4. Shear wall system

5. Core and outrigger structural system

6. Infilled frame structural system

7. Flat plate and flat slab structural system

8. Tube structural system

9. Coupled wall system

10. Hybrid structural system

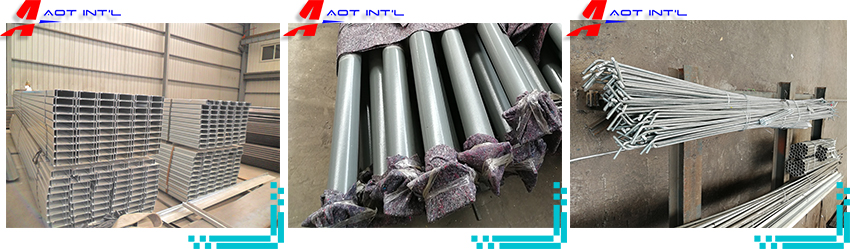

Steel Structure Technical Specifications |

| Main steel structure | Q235, Q345 steel, Welded type H section. Box section frames |

| Surface Treatment | Sa2.5 grade shot blasting, Alkyd painting, or Epoxy zinc-rich painting, or Galvanization according customers' requirements |

| Purlins | C section, Z section profiles, Electro-galvanized, 40g/m2, 60g/m2, 90g/m2, 275g/m2, according customers' requirements |

| Bracing system | Including Cross brace, Column brace, Knee brace, Batter brace, Tie bar etc. |

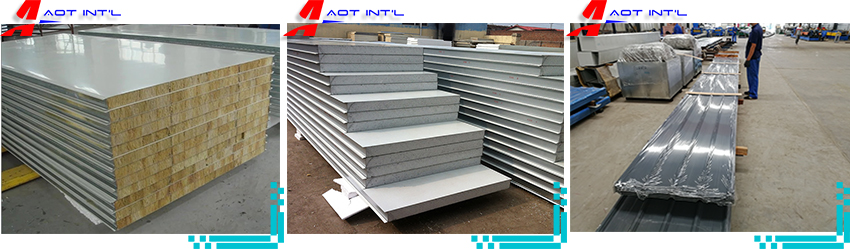

| Wall & Roof cladding system | Single corrugated galvanized metal sheet, or Insulated sandwich panels, such as Rockwool, Fiberglass, EPS, PU etc. |

| Doors | Electric Roller shutter door, or Sliding door, or Singe open / Double open door |

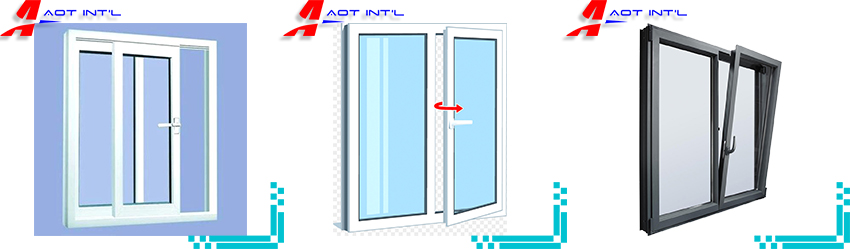

| Windows | UPVC / Aluminum windows |

| Rainspout system | Galvanized gutter, UPVC down pipes |

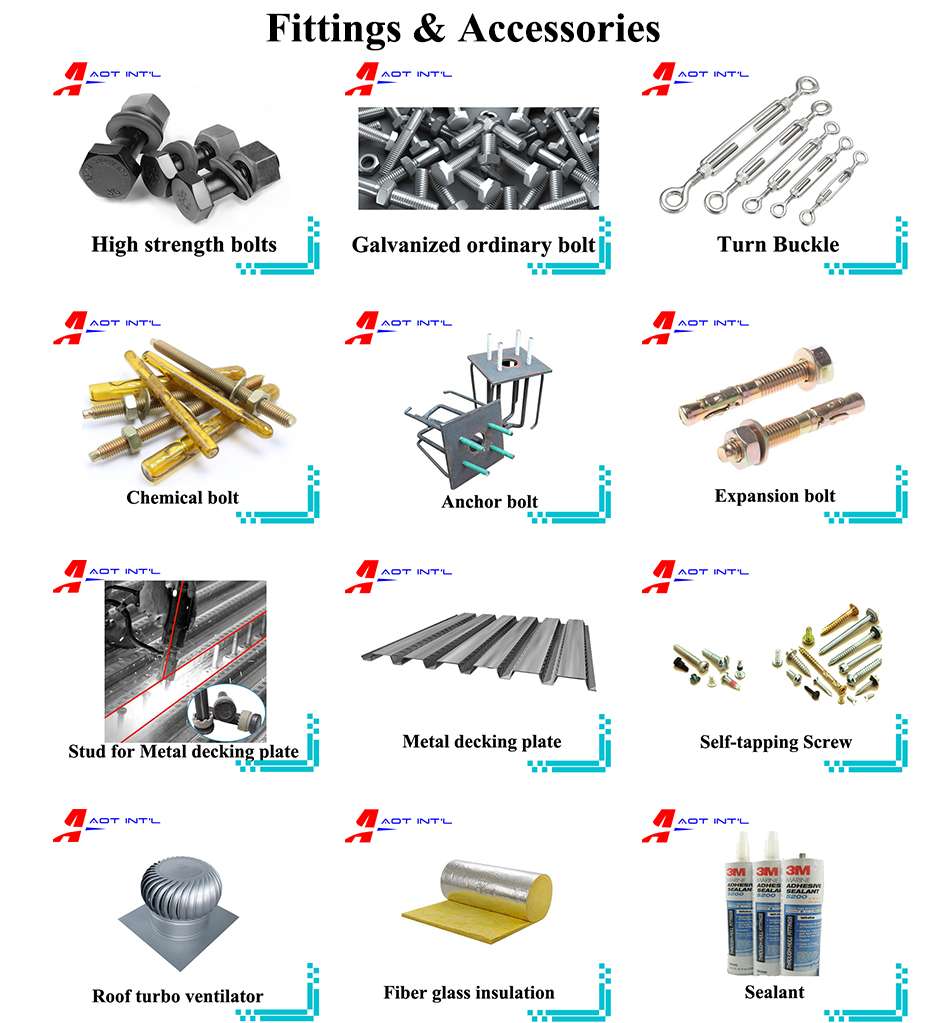

| Fittings & Accessories | Anchor bolt, High-strength bolt, Screw, Trim plate, Sealing glue etc. |

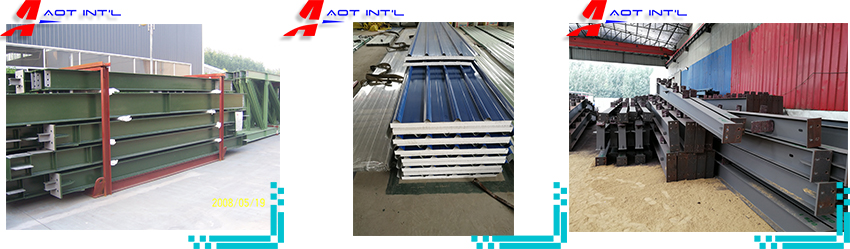

Main steel structure: Steel frames, H type, I type, Box type |

Brace: C section / Z section purlin, Round steel rod, L steel brace |

Wall & Roof cladding system: Sandwich panels, Galvanized color steel sheet (Check for more details) |

Industrial door: Roller shutter door, Sliding door, Steel door (Check for more details) |

Windows: Aluminum window, PVC window, Sliding window |

Fittings & Accessories: Anchor bolt, High strength bolt, Turn buckle, Metal decking plate, Stud, Sealant etc. |

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector