Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

The whole system of Poultry farm system is a quite wide range products, it will be headache for clients to collect all the facilities together. But now AOT will help to provide ONE-Stop & All-in-one solutions. AOT has established itself as a solutions provider of innovative poultry equipment and systems in the poultry sector. We focus on designing, developing, manufacturing, supplying, training and servicing poultry farm equipment and poultry farm systems. With a dedicated team of experienced staff, we are able to provide comprehensive and flexible services to support poultry farmers to get better results.

The range of AOT service comprises: PEB Chicken rearing house system, pan feeding system, chain feeding system, feed storage and transportation system, manual feeder, nipple drinking system, bell drinker, auto chick drinker, climate control system, mist cooling system, drop curtain system, light trap and breeder nest.

AOT also pay great attention to operation detail of our system with continuously upgrade in design that produce a very practical system. With our senior and dynamic workforce, we committed ourselves to produce quality, efficient and reliable system that simplifies the daily operation work in poultry farming.

The poultry farm system mainly including:

|

|

|

|

| PEB Chicken Rearing House | Feed Delivery Storage System | Feeding System | Nesting System |

|

|

| ...More... |

| Climate Control System | Flooring System | Watering System |

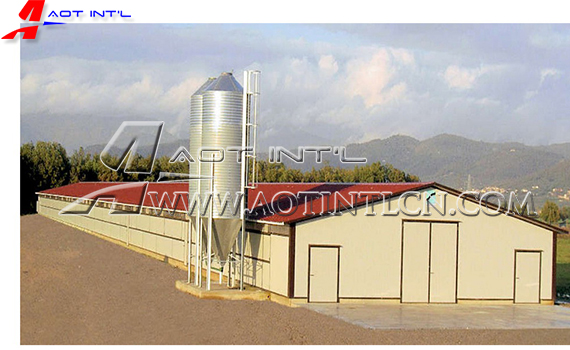

◆ 1) PEB Chicken Rearing House (Check for more details) |

AOT offers multiple options for your farm needs be it for poultry or for swine. Our track record shows that growers using AOT structures recorded high livability rate and save significant cost on long term maintenance. Our house are constructed to be energy savings and to withstand strong winds.

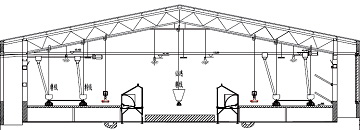

Design Concept:

Type: Open type chicken house /Closed type chicken house

Width: For Open type chicken house, typical width is 6~10meters;

For Closed type chicken house, typical width is 12~15meters;

Length: In generally it will depend on the width and the mechanization levels. If the width is 6~10meters, the length could be around 30~60meters; If the width is large like 12meters, the length could be around 70~80meters, but the Maximum length should be less than 120meters;

Height: It will be designed according the rearing type, width, manure removal type and climate information; The typical height will be 2~2.5meters; If it is the cage rearing type, and the height should be around 3meters; If there were manure removal system under cage, the height should be around 4.5~5meter.

◆ 2) Feed Delivery Storage System |

AOT automatic delivering system is comprised: Silo, Silo lid, Heavy strength ladder, Support steel frames, Driving system, PVC tubing and Quality auger etc. It increase management efficiency, reduce cross-infection and realize high automation of production process in the whole farm.

Features: Including feed container, lid, ladder, support legs etc. The feed container components are galvanized rugged metal sheet with zinc coating thickness of 275g/m2. View window on sidewall, allow you to easily check the level of feed in the silo, and the silo capacity is optional.

◆ 3) Feeding System |

There will be different feeding system to meet the various requirements, according to our experiences, we recommend the following listed types:

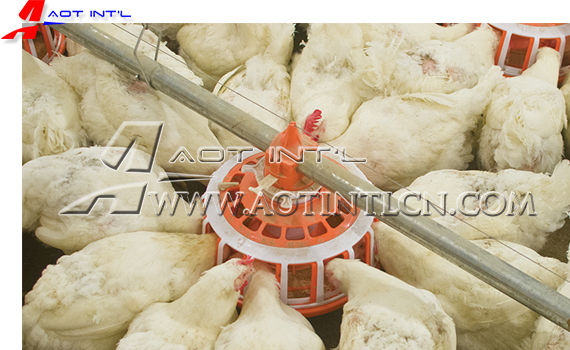

※ Broiler Pan feeding system

※ Breeder Pan feeding system

※ Breeder Chain feeding system

※ Broiler Pan feeding system

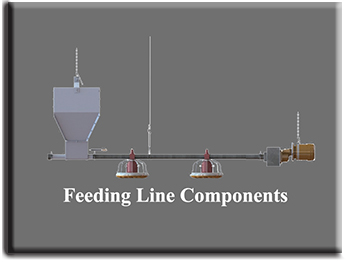

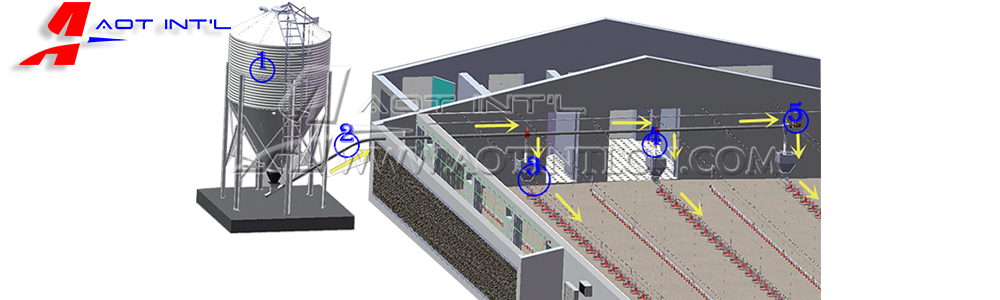

Main feeding system layout

1). Silo; 2). PVC tube; *3). Feeding line; 4). Drop tube; 5).Drive motor

*3) Feeding line components:

| Hopper /Tubing & Auger /*Pan feeder /Feed sensor & drive motor /Hang piece /Anti-roost piece |

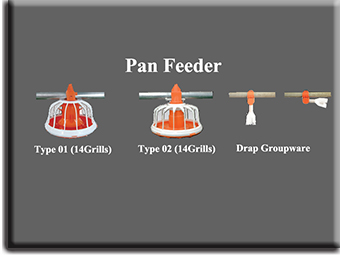

* Pan Feeder features

| # Type 02 feed pan has 5 feed level, Other feed pans have 10 levels to adjust. # Slide shutter-off can adjust feed amount from complete open to complete close. # Pan plate can be disassembled on the ground working as special pan for 0-7 days old chicken. # V-pan plate design can reduce feed storage at pan bottom. Bird can have fresh feed every day. # Edge of pan plate tilt towards the center which can avoid the waste of feed. # Smooth edge can prevent the bird craw from hurt and make sure safety and comfort feeding. # Assemble type of the pan in the pipe can be fixed or swing. |

※ Breeder Pan feeding system

|

|

|

|

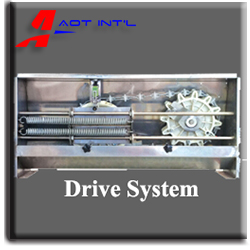

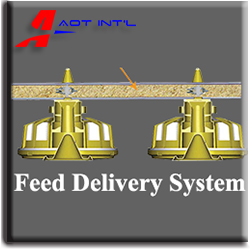

| Drive system: Gear Motor: 1.1kw or 1.5kw. Feed delivery speed V = 30m/min or 40m/min Drive system shell: stainless steel Driving (driven) wheel: reinforced nylon Designed with safety pin &chain tighten device and emergency stop switch | Delivery system: Feed pipe: 4 hole /3 m pipe Diameter of feed pipe: φ45mm Material of feed pipe: hot galvanized steel, galvanizing thickness 275g/㎡ Pipe thickness: 1.2 mm Feed delivery capacity: 900kg/h Feed pipe could reserve 400-500g feed per meter | High-strength disc chain: Long lasting and anti- fracture Disc is durable and resist breakage, Breaking force : 1.6tons | Non-feed remaining corner: Corner and corner shell material: hot galvanized sheet or stainless steel; Idler material: cast iron |

Please contact AOT for more details regarding "Female breeder pan feeder Main features" & "Male breeder pan feeder Main features"

※ Breeder Chain feeding system

Main feeding system layout

1). Feed trough support; 2). 900 corner; 3). Feed trough; 4). Feed trough cover plate

Features:

Drive device adopt vertical reducer motor, it represents the classic, proven technique for even, low-stress distribution of feed providing equal access of feed to all birds and assuring uniform development. Delivery speed reach up to 36m/min.

1). Feed trough support: the height of feed trough can be adjusted according to different raising periods, the support is made of high intensity nylon material, antiseptic and anti-corrosion, more suitable for poultry house environment.

2). 90o corner: it adopts self-lubricating synthetic bearing sleeve, the wheel and guide rail are specially hardened, the polycarbonate transparent cover is more durable and visible, it is convenient to detect the interior device, it has the characteristics of easy maintenance, wear resistance and long service life.

3). Feed trough: it is made of anti-rust material, and grill with 44mm distance can effectively separate the male and female birds, the space could be customized according to customer specifications too.

4). Feed trough cover plate: it is the interface part of feed box and feed trough, to avoid feed overflow.

◆ 4) Nesting system |

AOT Roll-Out Nest features a comfortable, safe and easily accessible laying area reducing bird stress and promoting enhanced hatchability. The typical design is as below:

LOW-HIGH-LOW MODE HIGH-LOW-HIGH MODE

Main features:

# Nest with large space, which enable to accommodate 4-5 chicken to lay eggs at same times(8-10 chickens at peak time);

# Soft nest pads are easy to clean and provide a comfortable and inviting laying area;

# The red curtain which is in front of the nest, attract flocks to lay eggs, ensuring internal flocks free from outside interference;

# Needle-shaped egg nest structure, can make fresh eggs do not contact foreign bodies, protect the egg surface is not contaminated;

# After completion of laying, eggs quickly slip into the conveyor belt with square hole, avoiding the chickens to peck eggs;

# The conveyor belt with square hole is made of heavy-duty plastic, ensure the smooth belt operation. The belt is with good ventilation to improve hatchability;

◆ 5) Climate control system |

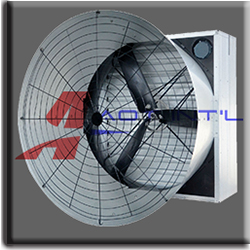

With decades of experience, non-stopping engineering and field refine, AOT ventilation systems are the perfect solution for high efficiency, outstanding performance, unbeatable durability and intelligent controlling ability, and most importantly, optimized birds production.

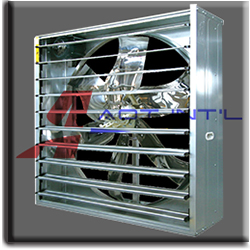

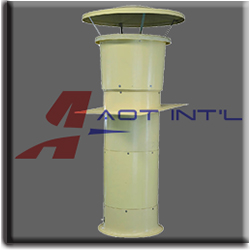

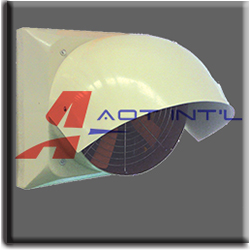

* Ventilation Fan

AOT offers a wide variety ventilation fans, from shutter to damper, from GI to Fiberglass, from 24” up to 56”, with different motors and blades, to achieve the best cooling effect for the poultry farm.

|

|

|

|

| Cone Fan 50” energy saving type | Box Fan Axial-flow fan with automatic shutter opening system | Roof ventilation Fan Roof fan with cover and automatic shutter opening system | Variable Speed Fan Flow is adjustable with automatic shutter opening system |

* Air Inlet

| Keep your air circulating smoothly with the use of AOT’s selection of air inlets, which provide precise control and distribution of incoming air flow into or out of any type of ventilation systems. To achieve maximum return on your investment, efficient ventilation systems are a necessity. Inadequate airflow in hot conditions increase stress on your animals, and can have a negative effect on their development. |

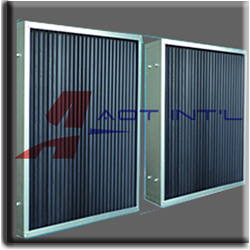

* Evaporative Cooling Pad

AOT evaporative utilize the natural cooling effect of evaporation to combat seasonal dips in production caused by heat stress. The cooling pad is made of high quality cellulose rigid media, impregnated with corrosion resistant and wetting additives to achieve the maximum durability and high cooling performance. The unique structural design gives strong self-support, low maintenance and low pressure drop characteristics.

| Features: Speciation: thickness: 0.1m /0.15m. Height: 1.5m/1.8m/2.0m.Width: 0.6m Frame: 2 options, galvanized or aluminum alloy |

* Light Trap

AOT Light Trap is made to be used for exhaust side and air inlets areas in tunnel ventilation system to achieve blackout without any significant loss of airflow.

| Features: # Highest reduction of light # Least resistance to air flow # Simple installation # Cool light trap is made of non-glare black plastic material that is resistant to sunlight, chemicals, pressure # Light trap pieces are framed in a Galvanized steel module box |

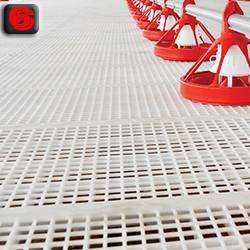

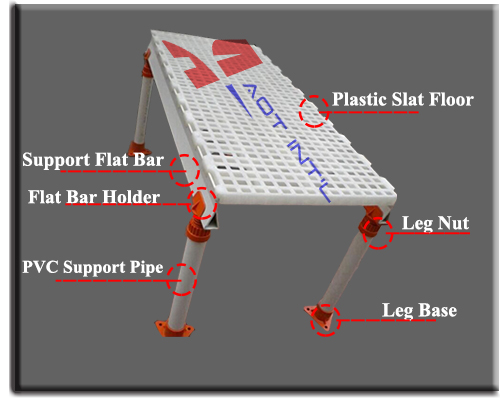

◆ 6) Flooring system |

AOT Poultry Flooring is made from high-impact, wear resistant polypropylene plastic (PP) designed to replace wood or wire slats in poultry housing.

AOT Slatted floor reduces foot pad related disease and breast blisters often experienced with wooden slats and will easily outlast them.

| Features: # AOT solid plastic construction is rot/corrosion proof, resists microorganisms’ build-up and sheds waste efficiently. # AOT poultry flooring is made from high impact polypropylene plastic (PP) material for durability & easy cleaning. # Corrosive free does not hide contaminants or harbor bacterial growth. # Available with or without UV protection. # Strong enough to hold 120kg (265lbs) of body weight to stand or walk. |

| Adjustable Leg Stand Support system |

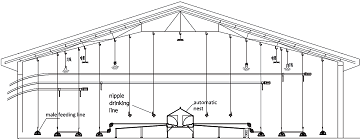

◆ 7) Watering system |

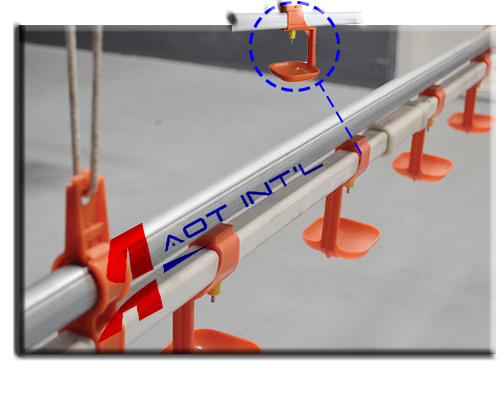

AOT Nipple Watering System works well in hot climates and in totally controlled environment house. Starts from day one to grow stage, chicks can trigger water flow by pecking nipple pin side or upwards from any direction 3600 , Our watering system provides high water flow rate which will result in better feed conversion and weight gains.

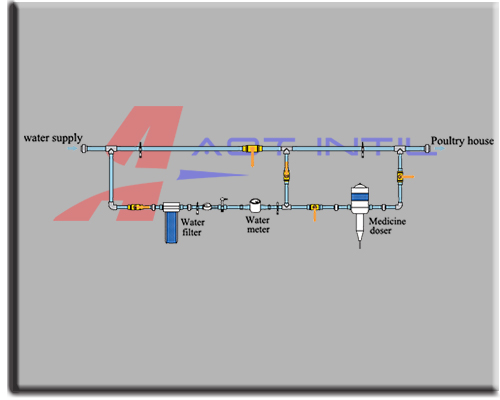

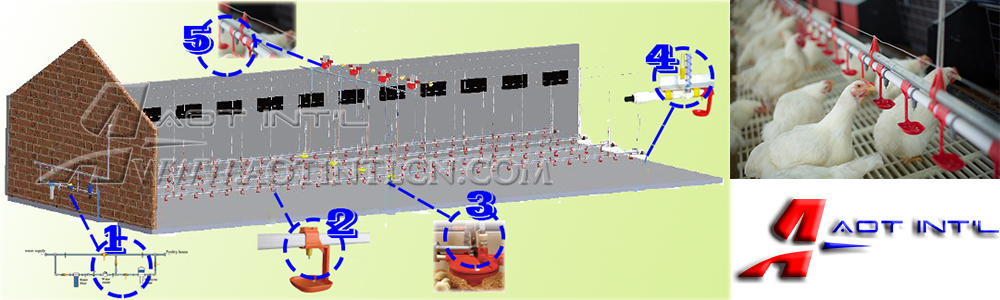

Nipple Watering System Main Layout

1). Watering system front part; 2). Nipple drinker part; 3). Water regulator; 4). End vent kit; 5). Water line holder part

| * 1). Watering system front part | Quality of the water is of high importance to most drinking system. Special design of our front part not only can supply water and dose medicine, but also wash sediment and dirt effectively with its large diameter clean-tube. All these can protect the system and reduce the workload. |

|

| * 2). Nipple drinker part | Square pipe supported by Aluminum Profile with simple holder makes installation fast and simple. Using AOT heavy gauge galvanized (both outer and inner) Support Conduit Pipe that gives almost maintenance free result. # 3600 soft trigger nipple can be used immediate on the 1st day rearing. # 120cc/min high flow rate of watering can be achieved during grower stage. # Drip cup will help to keep the litter dry. # Nipple Pipe and aluminum Profile support are totally rust resistance components |

|

| * 3). Water regulator & End vent kit | Optimum water pressure can be maintained by pressure regulator at all bird age. Water regulator allows adjustable pressure with high volume of water supply, Flushing water lines is even easier and simpler, just turn the handle from Regulate to Flush, water will flushes out through the Auto Flush Kit installed at the end of the lines. |

|