Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer's requirements.

Pre-engineered steel buildings are used for diverse applications such as:

| Industry: | Commercial: | Public: |

| ★ Warehouse; | ★ High-rise building /Multi floor building; | ★ Prefabricated schools /Classrooms; |

| ★ Workshop; | ★ Shopping mall; | ★ Sports arenas & sports hall; |

| ★ Factory /Plant; | ★ Distribution centers /Showrooms; | ★ Church building; |

| ★ Cold storage building; | ★ Steel structure hotels; | ★ Steel structure hospital; |

| ★ Power plants; | ★ Car parking center; | ★ Steel frame pedestrian bridge; |

| ★ Airplane hangars & aviation hangars; | ★ Poultry farm; | ★ Garage; |

| ★ Storage shed; | ★ Agricultural building & barns; | ★ Community center; |

| ★ Self-storage building; | ★ Green house; |

Pre Engineered Agricultural Steel Building Metal Barns: |

Pre-engineered Steel Structure Agriculture Grain Storage Building

The Steel Framed Agricultural Building Kits, is initially a steel hall (a steel structure clad in steel), is then equipped with the necessary equipment for the purpose in question. Insulation, heating, lighting and ventilation, dehumidification, as well as vehicle doors and ramps, are all examples of the equipment needed to create a barn, workshop hall, food warehouse , animal husbandry or production and storage of vegetables and grains.

These days a Steel Structure Farm Building Steel Building Farmhouse serves as an equipment storage shed, a warehouse, a milking parlor, a free stall barn or a workshop. Or it can combine several different uses with an office thrown in, too. These buildings are no longer just barns. We emphasize animal comfort and ventilation, high ceilings and big doors for equipment, weather-tight buildings for crops, and much more.

Steel Structure Agriculture Storage Warehouse

If you’re going to build a Prefab Steel Agriculture Storage | Industrial Steel Building, you’d better do it right. It takes a durable structure to withstand the forces of mother nature, gravity, animals and more. Here are some tips for building a Prefab Metal Agricultural Storage Building with durability in mind.

Make sure the building is properly engineered. When contracting for a building, you need to know that the person or company designing it will think about the entire scope of the building and the construction process. That involves considering the building’s purpose, the soil conditions and exposure, the materials being used to construct it, and how those materials are put together.

A reputable steel structure building company with construction standards designed by licensed, professional engineers, like AOT, will consider all these factors. AOT will send the completed plans with a set of construction details to the crew erecting the building. This will help ensure that it is built as designed in every detail, which provides the greatest longevity and least amount of maintenance for your building.

Animal Husbandry Agricultural Steel Structure Buildings

Use high-quality materials. Steel, door and window materials are the most important materials involved in building a post-frame steel structure. Here’s what to look for in each:

Steel is the skin (and muscles) of the building. And all other things being equal, the stiffer the steel, the stronger the building.

Windows and doors. Only use high-quality materials for windows and doors. You might pay more upfront, but you’d pay a lot more later when that door has a bent hinge or the frame is rotting out because it wasn’t properly sealed.

A high-quality door and window will last the life of the building. You can’t say the same for cheaper doors and windows that will likely need to be replaced every 10 to 15 years.

Hire a good crew. A good crew understands the engineering behind a building’s design, and they adhere to those specific guidelines set by the designer. If they don’t, the building’s durability will suffer.

A reputable crew also uses the proper power tools required for building a durable structure. Always remember, crew of four with the proper electrical tools, lifts and training will produce a building that is far superior to a 12-man crew with hand-powered saws and hammers.

Include durability features. Several additional features can also improve the durability of your building – especially when it comes to Prefab Steel Structure Agriculture Storage Shed.

Prefab Steel Agriculture Equipment Storage Building

Steel Structure Technical Specifications |

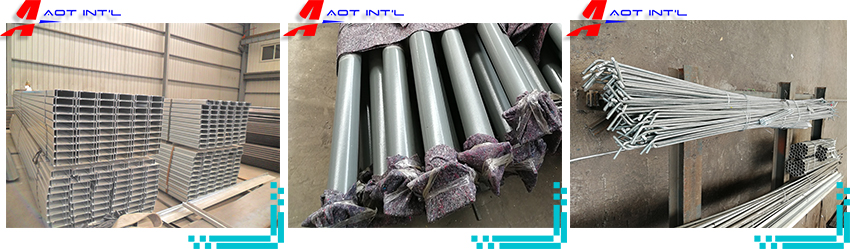

| Main steel structure | Q235, Q345 steel, Welded type H section. Box section frames |

| Surface Treatment | Sa2.5 grade shot blasting, Alkyd painting, or Epoxy zinc-rich painting, or Galvanization according customers' requirements |

| Purlins | C section, Z section profiles, Electro-galvanized, 40g/m2, 60g/m2, 90g/m2, 275g/m2, according customers' requirements |

| Bracing system | Including Cross brace, Column brace, Knee brace, Batter brace, Tie bar etc. |

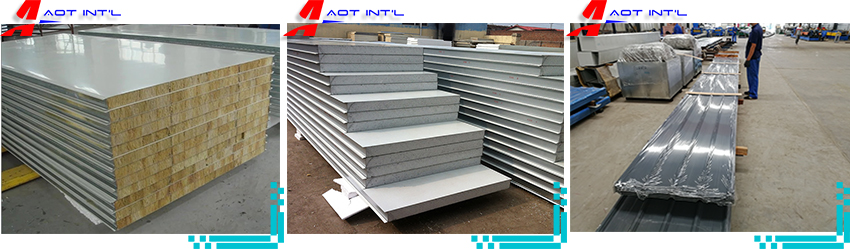

| Wall & Roof cladding system | Single corrugated galvanized metal sheet, or Insulated sandwich panels, such as Rockwool, Fiberglass, EPS, PU etc. |

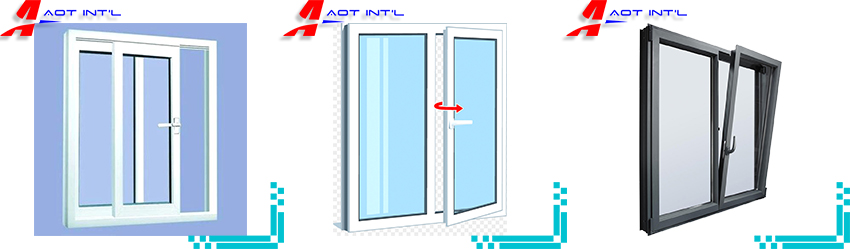

| Doors | Electric Roller shutter door, or Sliding door, or Singe open / Double open door |

| Windows | UPVC / Aluminum windows |

| Rainspout system | Galvanized gutter, UPVC down pipes |

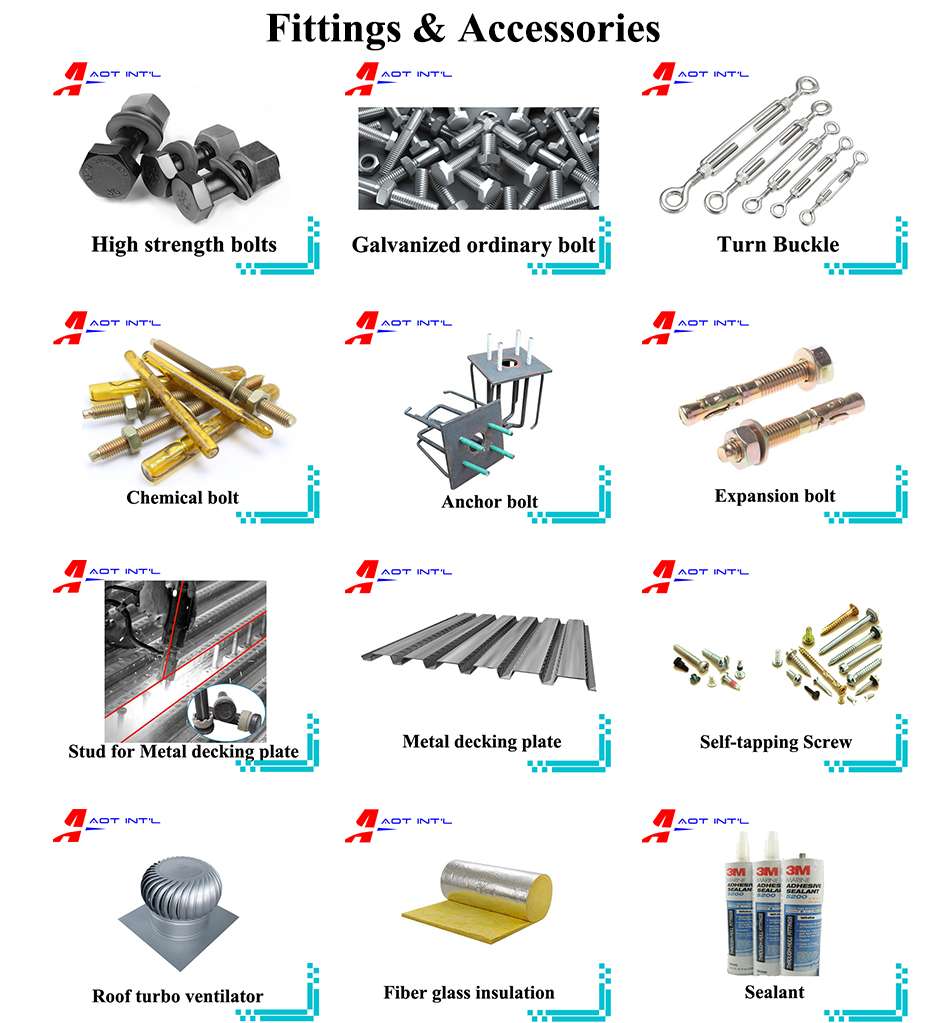

| Fittings & Accessories | Anchor bolt, High-strength bolt, Screw, Trim plate, Sealing glue etc. |

Main steel structure: Steel frames, H type, I type, Box type |

Brace: C section / Z section purlin, Round steel rod, L steel brace |

Wall & Roof cladding system: Sandwich panels, Galvanized color steel sheet (Check for more details) |

Industrial door: Roller shutter door, Sliding door, Steel door (Check for more details) |

Windows: Aluminum window, PVC window, Sliding window |

Fittings & Accessories: Anchor bolt, High strength bolt, Turn buckle, Metal decking plate, Stud, Sealant etc. |

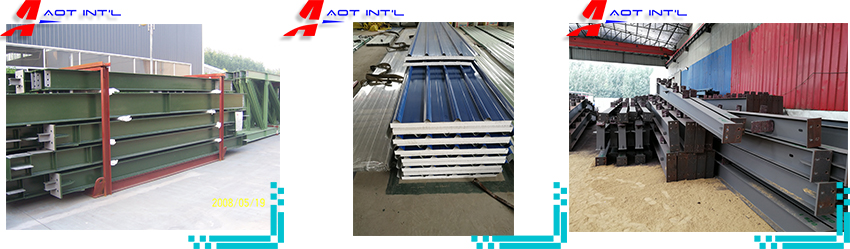

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector