Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer's requirements.

Pre-engineered steel buildings are used for diverse applications such as:

| Industry: | Commercial: | Public: |

| ★ Warehouse; | ★ High-rise building /Multi floor building; | ★ Prefabricated schools /Classrooms; |

| ★ Workshop; | ★ Shopping mall; | ★ Sports arenas & sports hall; |

| ★ Factory /Plant; | ★ Distribution centers /Showrooms; | ★ Church building; |

| ★ Cold storage building; | ★ Steel structure hotels; | ★ Steel structure hospital; |

| ★ Power plants; | ★ Car parking center; | ★ Steel frame pedestrian bridge; |

| ★ Airplane hangars & aviation hangars; | ★ Poultry farm; | ★ Garage; |

| ★ Storage shed; | ★ Agricultural building & barns; | ★ Community center; |

| ★ Self-storage building; | ★ Green house; |

Prefabricated Steel Structure Self Storage Buildings: |

The mini-storage industry has seen consistent growth over the past years, making it an enticing business opportunity for entrepreneurs and large operators. AOT Prefabricated Steel Structure Self Storage Buildings can get your business off the ground in a matter of weeks with quick delivery and construction. Our versatile buildings allow for future expansion and include flexible divisions, so you’re able to modify the size of each unit according to rental needs.

| AOT Steel Structure Building | Metal Storage Building Self Storage |

| |

| AOT Steel Structure Building | Light Prefabricated steel structure Self Mini Storage Buildings |

With AOT Steel Structure Building, here are some advantages to building a prefabricated storage building:

Portable

With a prefabricated building, it is easy to move the whole building to another spot if you need to. Grab your tools and take apart the building, then move it and build it again somewhere else!

Customizable and Versatile

A prefab building has lots of custom building options and is easy to manipulate into something that fits your specific needs.

Another neat feature of using a prefabricated building is how easy it is to attach a more prefabricated structure later on if you ever need to expand your storage space.

| AOT Steel Structure Building | AOT Self-Storage Building Kits |  |

| |

| AOT Steel Structure Building | AOT Steel Mini Storage Building |

Ease and Speed of Construction

With a prefabricated structure, careful engineering ensures everything has a perfect, snug fit. You won’t need to worry about making changes to the building plans which cost precious time and money.

Prefab Storage Building Durability

Prefabricated storage facilities have the engineering and strength to be able to withstand hurricane-force winds. Likewise, as well as the ability to support the weight of a hefty snowstorm. This all-weather feature makes the prefabricated style of building a great choice for any climate you might need.

Lower Construction and Maintenance Cost

While we are on the topic of saving money, construction and maintenance costs for prefab storage is way less than traditional buildings.

If you were to build a new single-level storage facility in the traditional “brick and mortar” style, you could be spending from up to per square foot whereas a prefabricated building will cost somewhere between and per square foot.

As far as long-term maintenance goes, prefab storage facilities outlast even the best wooden frame structures which are prone to warping and rotting over time.

Prefabricated Steel Structure Self Storage Buildings Technical Specifications |

| Main steel structure | Q235, Q345 steel, Welded type H section. Box section frames |

| Surface Treatment | Sa2.5 grade shot blasting, Alkyd painting, or Epoxy zinc-rich painting, or Galvanization according customers' requirements |

| Purlins | C section, Z section profiles, Electro-galvanized, 40g/m2, 60g/m2, 90g/m2, 275g/m2, according customers' requirements |

| Bracing system | Including Cross brace, Column brace, Knee brace, Batter brace, Tie bar etc. |

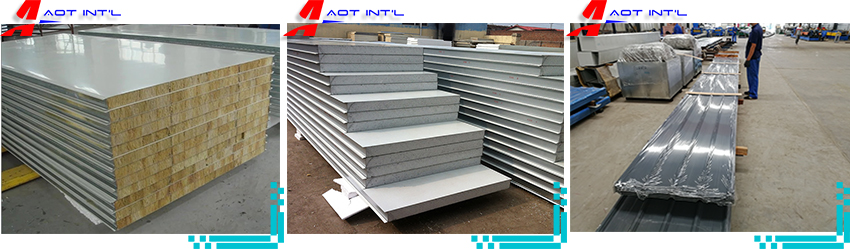

| Wall & Roof cladding system | Single corrugated galvanized metal sheet, or Insulated sandwich panels, such as Rockwool, Fiberglass, EPS, PU etc. |

| Doors | Electric Roller shutter door, or Sliding door, or Singe open / Double open door |

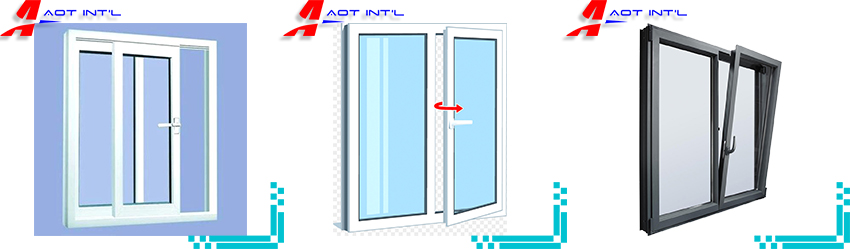

| Windows | UPVC / Aluminum windows |

| Rainspout system | Galvanized gutter, UPVC down pipes |

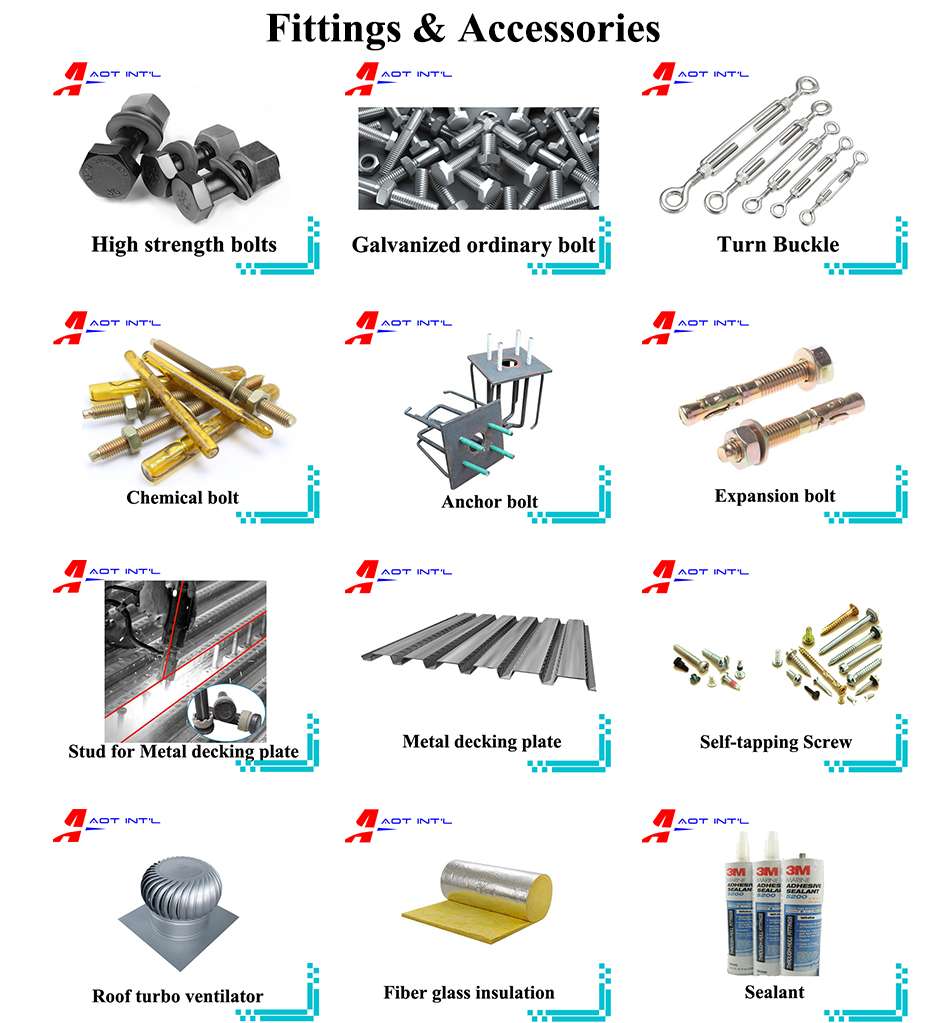

| Fittings & Accessories | Anchor bolt, High-strength bolt, Screw, Trim plate, Sealing glue etc. |

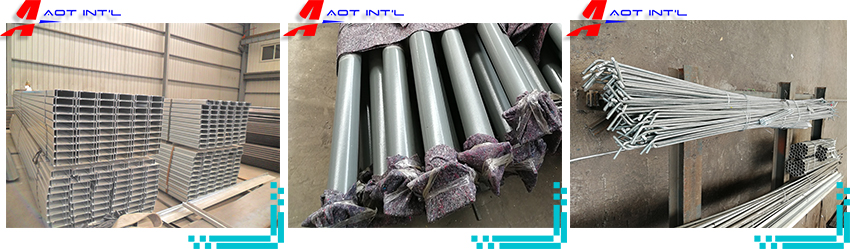

Main steel structure: Steel frames, H type, I type, Box type |

Brace: C section / Z section purlin, Round steel rod, L steel brace |

Wall & Roof cladding system: Sandwich panels, Galvanized color steel sheet (Check for more details) |

Industrial door: Roller shutter door, Sliding door, Steel door (Check for more details) |

Windows: Aluminum window, PVC window, Sliding window |

Fittings & Accessories: Anchor bolt, High strength bolt, Turn buckle, Metal decking plate, Stud, Sealant etc. |

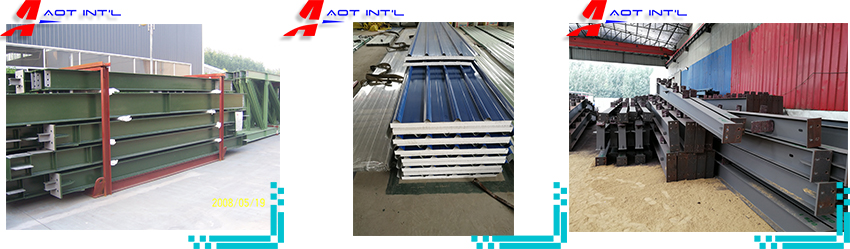

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector