Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

Prefabricated building / Prefab house is built with light steel frames and kinds of sandwich panels. Basically there were 2types of prefab house system: K type prefabricated house and T type prefabricated house.

Prefabricated building / Prefab house are used for diverse applications such as:

| ★ Prefabricated camp building; | ★ Construction accommodation camps; | ★ Defense & Military Labor camps; |

| ★ Mining & gold labor camps; | ★ Oil & Gas workers camps; | ★ Prefabricated office building; |

| ★ Prefabricated hospital & clinics; | ★ Prefabricated classroom; | ★ Prefabricated accommodation building; |

| ★ Prefabricated Kitchen & Canteen; | ★ Temporary building; | ★ Prefabricated Sanitary & toilet & shower building; |

| ★ Prefabricated recreation building |

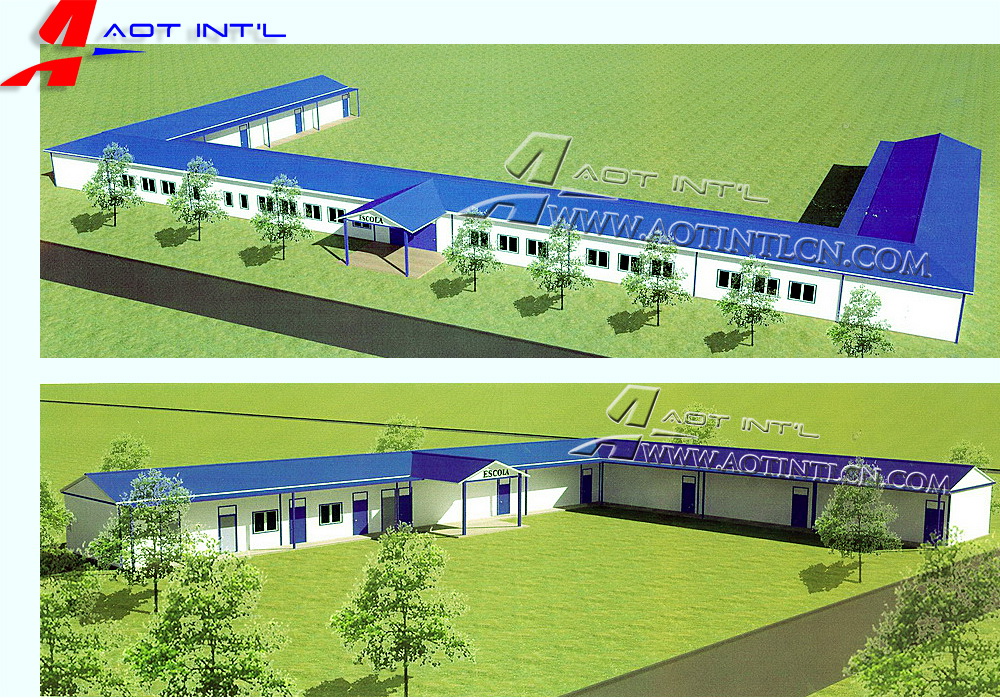

Easy Construction Prefabricated School Classroom |

AOT Steel Structure Building | Easy Construction Prefabricated School Classroom 3D design

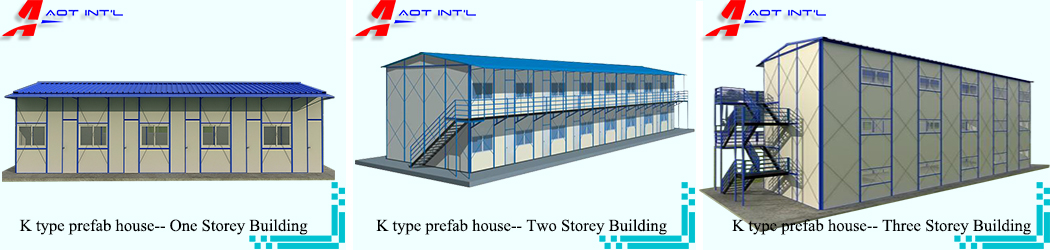

K type prefabricated house system |

1 (ONE) Storey / 2 (TWO) Storey / 3 (THREE) Storey K type Prefab House

The columns are double C section profile steel, and rafter is pre-welded tri-angle beams. The roof and wall panels could be Rockwool, Fiberglass or EPS insulated sandwich panels with different thickness like 50mm, 75mm or 100mm. Comprising with other components like light steel doors, Aluminum / PVC windows, gypsum board suspended ceiling, plastic floor leather, electrical system and Sanitary facilities & plumbing etc. to be a self-contained temporary house units.

The K type prefabricated house is a modular building system, there were its standard dimensions, the width could be 5560mm, 6230mm or 7360mm, while the length could be N*K (K=1800mm), and the height could be 3P, 6P or 9P (P=950mm, 3P is single floor, 6P is two floors and 9P is three floors)

T type prefabricated house system |

1 (ONE) Storey / 2 (TWO) Storey / 4 (FOUR) Storey T type Prefab House

The main difference of T type prefab house from K type prefab house is the steel columns are invisible from outside, thus appearance is better and there will be a better airtightness performance to make the insulation good for heat, wind and sand, it widely used in sandy weather like Middle east and rainy weather like South Asia. Another important difference is T type prefab house is total customized according customers’ requirements, it could be built with any dimensions to fit the site condition properly.

The main columns will be the square tube while the rafter is same pre-welded tri-angle beams.

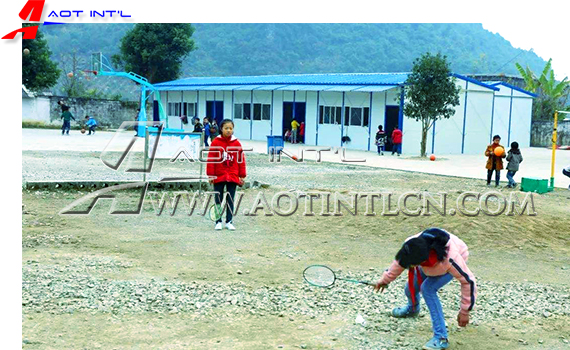

| AOT Steel Structure Building | Light Steel Modular Classroom Cabin |

| |

| AOT Steel Structure Building | Sandwich Panel Prefab School Prefab Classroom |

AOT Steel Structure Building proudly serve a diverse range of industries and sectors, with an unmatched ability to design and completely customize workforce solutions | modular buildings | Prefab house system to meet the needs or your unique project for:

◇ Mining Camps, Mine Site Infrastructure, and Remote Camps for Exploration

◇ Modular Construction and Construction Camps

◇ Oil & Gas Facilities, Oilfield Housing, and Man Camps

◇ Modular Housing, Camp Systems and Support Facilities for the Utility, Energy and Forestry Industries

Camp systems by AOT Steel Structure Building can be configured and scaled to accommodate crews and labor forces from 10 to 10,000 people. We understand companies operating in remote areas need onsite services and high-end levels of accommodation to attract and retain workers. At the higher end of the spectrum, companies wanting to provide their workers with hotel-like services including catering, housekeeping, laundry, and access to recreation activities and facilities. Depending on the modular housing requirement, workers and staff can be treated with private bedrooms and en-suite bathrooms or housed in bunkhouses with shared spaces.

The dedicated team at AOT Steel Structure Building will work with you and your project management team every step of the way, from initial planning, designing, engineering modular buildings for workforce housing or camp systems, site preparation, logistics, site service distribution, installation, and after the project is complete we offer relocation services.

If you would like to discuss your requirements further, simply get in touch with the team on ken@aotintlcn.com

| AOT Steel Structure Building | Modular Light Steel Framing Classroom |

| |

| AOT Steel Structure Building | Fast Assemble School House |

All AOT Steel Structure Building engineered modular buildings can be configured with innovative technologies to increase energy efficiency and comfort.

◇ HVAC and ventilation systems

◇ Lighting and electrical distribution systems

◇ Communication systems

◇ Hard-wall systems and partitions

◇ Windows and doors

◇ Skylights that utilize natural lighting during the day and reduce overall energy usage

◇ Proprietary insulation systems increase energy efficiency while providing a comfortable living or working space

Engineered fabric buildings by AOT Steel Structure Building offer many benefits and have been used for the following:

◇ Worker Dormitories, Staff Quarters, and Executive Dormitories

◇ Bunkhouses and Sleepers

◇ Fitness Centers

◇ Gymnasiums

◇ Weight Rooms

◇ Game Rooms

◇ Movie Theaters

◇ Commissary

◇ Cafeteria-Style Dining

◇ Food Storage, Preparation, and Serving Areas

◇ Mud Room

◇ Shower and Locker Rooms

◇ Medical Shelters and First-Aid Clinics

◇ Laundry Facilities

◇ Offices, Business Centers, Conference Rooms, and Administration Areas

◇ Security Areas

Easy Construction Prefabricated School Classroom Technical Specifications |

| Steel Column | 2C80*40*15*1.5 painting(K type) / Square tube (T type) |

| Tri-angle beam | Pre-welded C80*40*15*1.3/U50*35*1.3 electro-Galv. |

| First floor main beam | C80*40*15*1.5/U50*35*1.2 electro-Galv. |

| First floor secondary beam | C80*40*15*1.3 electro-Galv. |

| Roof purlin | L40*3 electro-Galv. |

| Ground channel steel | C80*40*15*1.3 electro-Galv. |

| Steel staircase | Square tube 30*30*2.0/40*40*2.0, 2.5mm checkered plate painting |

| Steel Corridor | 1.8mm galv. steel plate/L40*3/tube 40*20*1.0 painting |

| Roof panel | 50mm/75mm/100mm Fiberglass/Rockwool/EPS sandwich panel |

| Wall panel | 50mm/75mm/100mm Fiberglass/Rockwool/EPS sandwich panel |

| *Suspended ceiling (*Optional) | 6mm gypsum board with frame |

| First floor board | 18mm plywood board |

| *Floor leather (*Optional) | 1.5mm PVC floor leather |

| *Electrical system (*Optional) | Cable/Lights/Switch/Socket/PDB |

| *Sanitary facilities&plumbing (*Optional) | Ceramic toilet/washbasin/shower, input & output pipes |

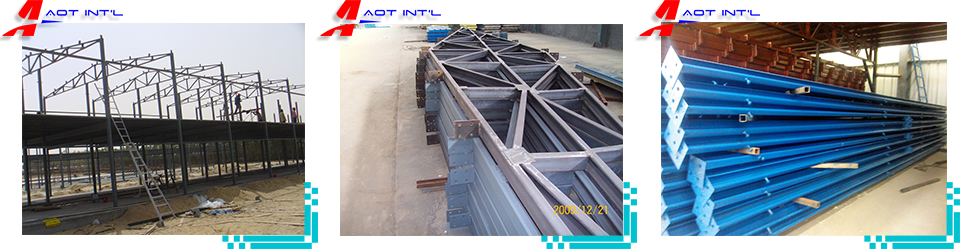

Prefabricated House Steel Framework: |

◆ Steel column: 2C80*40*15*1.5 painting (K type) / Square tube 80*80mm /100*100mm /120*120mm /150*150mm (T type)

◆ Tri-angle beam: Pre-welded C80*40*15*1.3/U50*35*1.3 electro-Galv.

◆ Wall and roof purlin: L40*3 (K type); C80/C100 (T type)

Prefabricated House Foundation & Flooring: |

◆ Foundation is simple strip foundation, in generally it will be 400*400mm

◆ Ground flooring will be Ceramic tiles or PVC floor leather

◆ First flooring will be 15mm/18mm plywood with 1.5mm PVC floor leather

Prefabricated House Ceiling System: |

◆ 6mm Gypsum board with frames for dry room

◆ 12mm PVC ceiling with frames for wet room

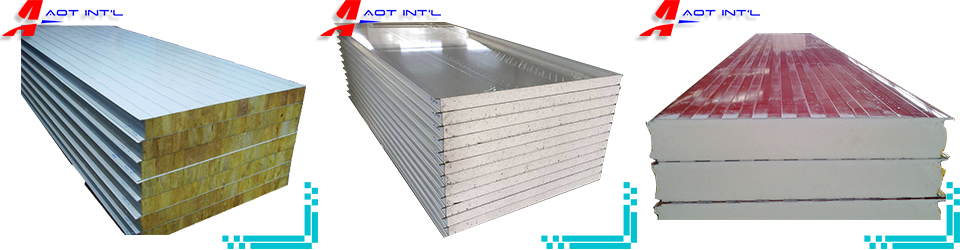

Prefabricated House Roof panel & Wall Panel (Check for more details): |

◆ Insulated Sandwich Panel

◆ Panel width: 950mm

◆ Thickness: 50-150mm

◆ Powder coated galvanized color steel on both sides: 0.4mm/0.5mm/0.6mm

◆ Insulation: EPS/Fiberglass/Rockwool

Prefabricated House Door Units (Check for more details): |

◆ Insulated light steel door, furnished with hardware&locker&keys

◆ Insulated sandwich panel door, furnished with hardware&locker&keys

◆ Plywood door /MDF Door, furnished with hardware&locker&keys

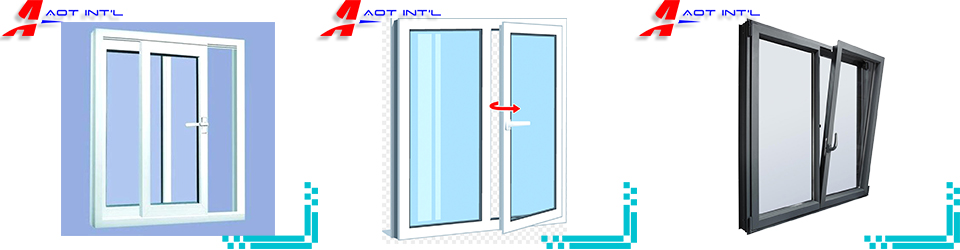

Prefabricated House Windows Units: |

◆ Aluminum windows with mosquito screen, 4mm glass

◆ UPVC windows with mosquito screen, 4mm glass

Other Optional Facilities (Check for details): |

Electrical Fittings:

◆ Electrical wire, 2.5mm2 for lighting system, and 4mm2 for AC units.

◆ Socket: 16A five holes universal socket.

◆ Light: double tube fluorescent lamp, 220V, 50-60HZ

◆ Single Switch, with junction box

◆ Electrical distribution box: box + breakers + earth leakage protective device

◆ Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC

Sanitary Ware & Plumbing:

◆ Western Close tool: ceramic, with pipes and installation fittings

◆ Urinal: ceramic, with pipes and installation fittings

◆ Wash basin: ceramic, with post, faucet, pipes and installation fittings

◆ Shower head, Shower base, Water mixture

◆ Water drainage pipe, PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years.

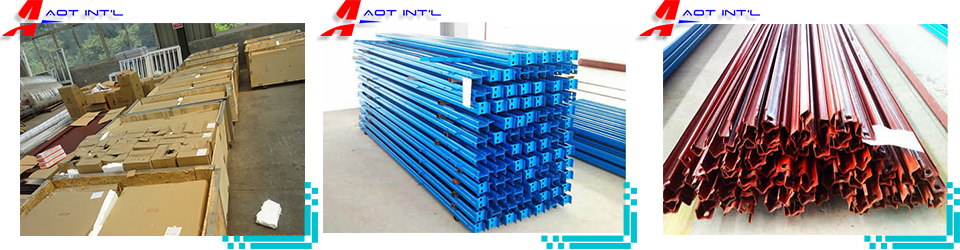

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector