Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

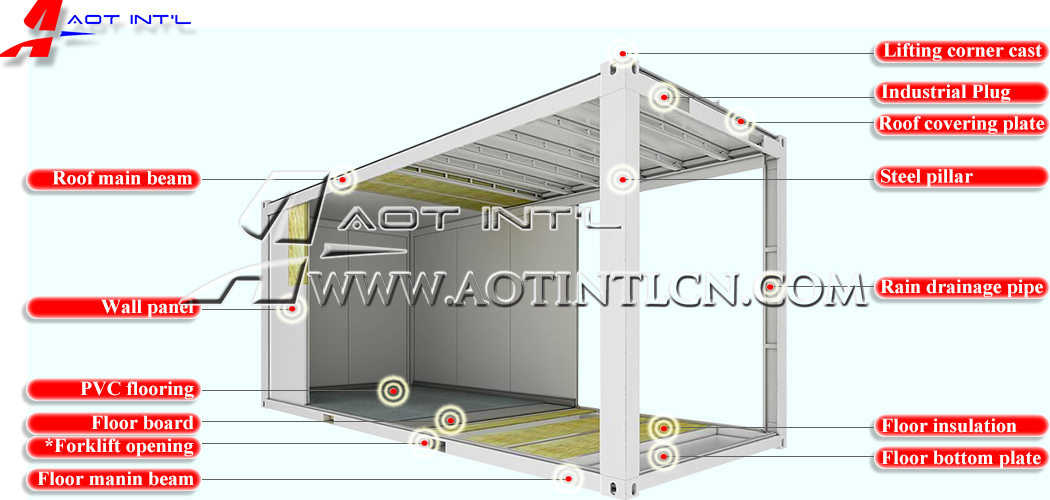

What’s flat pack? AOT flat pack container is the modular industrial prefabricated system, comprising Roof, Floor, Pillars and Wall panels (with doors/windows). AOT flat pack container’s dimension conform to ISO shipping container (20ft), the Roof & Floor is prefabricated ready in AOT factory. While it’s transportation, AOT will take the “All in one package” solutions, which means all the components of one modular container house will be packed in one Flatpack, including 1(ONE) Roof, 1(ONE) Floor, 4(FOUR) Pillars, All wall panels (including doors & windows) and all the other related accessories.

4(FOUR) pcs Flat pack units could be combined as one bundle, and the dimension is same as ISO shipping container, with ISO standard corner casts, are easy for transportation and crane lifts during the shipment. Further to the Flat pack transportation solutions, the flat pack container house could be loaded in to 40ft HQ shipping containers, which quantity will be 6(SIX) units per 40ft HQ shipping container. AOT Flat pack container house system could be combined in both horizontal and vertical, also could be stacked up to Max. 3floors, to make more large space for multi-purpose usage.

AOT Flat pack container houses are used for diverse applications such as:

| ★ Modular container worker camps; | ★ Portable office block; | ★ Construction site container house; |

| ★ Living containers; | ★ Service container building; | ★ Education container house; |

| ★ School and classroom portable container; | ★ Hospital container; | ★ Mobile clinic container; |

| ★ Health care container cabin; | ★ Dinning modular cabin; | ★ Kitchen and Canteen container block; |

| ★ Mobile toilet container; | ★ Movable lavatory container block; | ★ Gym cabins; |

| ★ Sports and clubs portable cabin | ★ Laboratory container | ★ Power house cabin |

Flat Pack Storage Containers Collapsible Storage Solutions |

AOT Steel Structure Building | FlatPack Storage Container Cabin

| AOT Steel Structure Building | Metal Storage Container Mobile Container Store |

| |

| AOT Steel Structure Building | Flat Pack Storage Containers Collapsible Storage Solutions |

Flatpack containers on-site storage modular containers

Flat pack containers, also known as modular site containers, consist of panels that slot together to create a sturdy storage solution.

The flat pack containers have been more commonly used due to their durable, yet lightweight features that make transportation easy and keep contents safe and secure. In fact, many flat pack containers offer impressive safety features that can discourage and even prevent theft of important tools and equipment stored within.

Construction contractors looking for quick, convenient and efficient storage will benefit from a flat pack storage container, particularly when there’s a need for storage but there’s limited space or restricted access.

| AOT Steel Structure Building | Construction Site Portable Container Storage Modular Cabin |  |

| |

| AOT Steel Structure Building | Multi-function Flatpack Storage Prefab Container Building |

Flat pack containers are easily transported because of their lightweight features, and can be dismantled just as effortlessly as they are constructed. This means that if you need more space, or don’t need the container, you can easily pack it away to create more room and re-construct it when needed again.

The speed at which these products can be assembled and disassembled is of particular use to contractors because it really means less time is spent on getting a storage area set up and more time is spent working on the task at hand.

Simply get in touch with our experienced team to discuss your requirements on ken@aotintlcn.com.

AOT Steel Structure buildings’ aim is to increase security, safety and productivity in the construction industry, so this high-quality modular site container has been designed and manufactured with that in mind.

Quick Assembly

Constructing the AOT Steel Structure building flat-pack container couldn’t be easier. These walk-in units are constructed using galvanized panels that slot together simply. Not only does this mean that the container can be assembled in as little as 2hours, the final result is a sturdy, weatherproof store that comes in multiple size and format options.

Easy to transport

AOT Steel Structure building--flat pack container features forklift pockets for easy transportation and lifting eyes for crane loading so you’ll have no trouble at all when it comes to moving in and out and around your site. Further to that, the entire container is designed to be lightweight, so moving panels around for assembly is easy - it can be assembled with just two people.

Secure on-site storage

With the theft of tools and equipment on the rise, security is a key factor when choosing flat pack containers. AOT Steel Structure building--flat pack container ensures security at all times.

If you would like to discuss your requirements further, simply get in touch with the team on ken@aotintlcn.com

Modular Flat Pack Container House Techical Specifications |

| Roof main frame Main beam | 3.0mm thickness Galv. with electrostatic spraying |

| Roof secondary frame | 80*40*1.3mm, galvanization |

| Floor main frame | 3.0mm thickness Galv. electrostatic spraying |

| Floor secondary frame | C120*60*1.7mm, galvanization |

| Corner pillar | 3.0mm thickness Galv. with electrostatic spraying |

| Lift corner piece | 6mm /10mm thickness corner cast |

| Roof covering plate | 0.5mm thickness Galv. metal steel sheet |

| Roof insulation | 100mm thickness fiberglass with PE foil |

| Roof suspended ceiling | 0.4mm Galv. metal sheet |

| Floor bottom covering plate | 0.23mm thickness Galv. metal steel sheet |

| Floor insulation | 100mm thickness fiberglass |

| Floor board | 18mm thickness fiber cement plate |

| PVC flooring | 1.6mm thickness vinyl leather |

| Wall panel | 50mm/75mm thickness fiberglass insulated sandwich panel |

| Door | Light steel single open door (845*2035mm) with locker |

| Window | UPVC sliding window,double glass with mosquito screen &security fence |

| Electrical System | Including PDB/industrial plug/socket/switch/lamp |

| Rain drainage pipe | 50mm PVC pipe |

Flat Pack Container House Roof Units: |

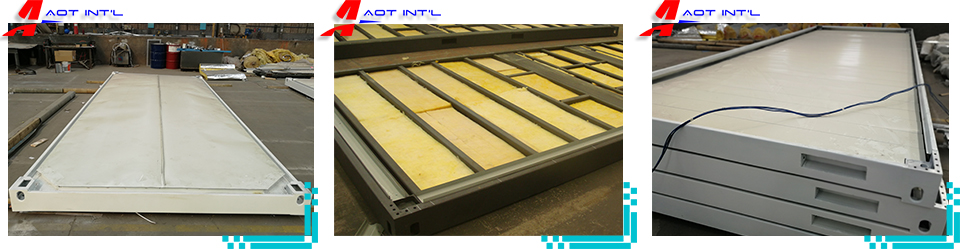

◆ Roof main frame--- Main beam 3.0mm thickness Galv. with electrostatic spraying

◆ Roof secondary frame--- 80*40*1.3mm galvanization

◆ Lift corner piece--- 6mm /10mm thickness corner cast

◆ Roof covering plate--- 0.5mm thickness Galv. metal steel sheet

◆ Roof insulation--- 100mm thickness fiberglass with PE foil

◆ Roof suspended ceiling--- 0.4mm Galv. metal sheet

Flat Pack Container House Floor Units: |

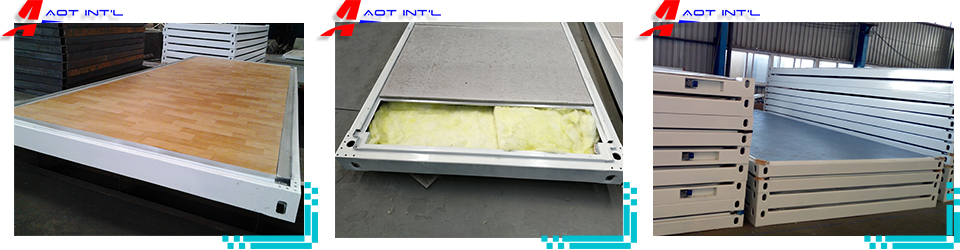

◆ Floor main frame--- 3.0mm thickness Galv. electrostatic spraying

◆ Floor secondary frame--- C120*60*1.7mm, galvanization

◆ Lift corner piece--- 6mm /10mm thickness corner cast

◆ Floor bottom covering plate--- 0.23mm thickness Galv. metal steel sheet

◆ Floor insulation--- 100mm thickness fiberglass

◆ Floor board--- 18mm thickness fiber cement plate

◆ PVC flooring--- 1.6mm thickness vinyl leather

Flat Pack Container House Corner Pillars: |

◆ Corner pillar--- 3.0mm thickness Galv. with electrostatic spraying

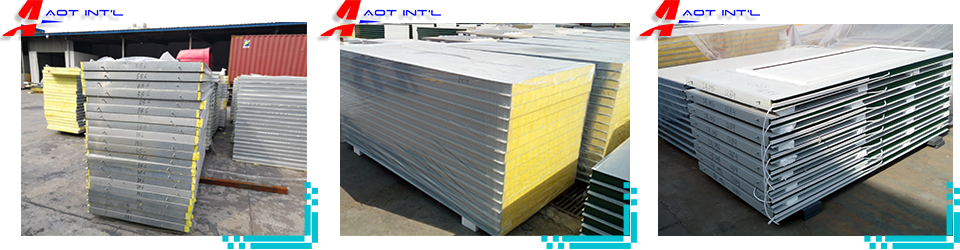

Flat Pack Container House Wall panels (Check for Sandwich panels details): |

◆ Thickeness: 50mm /75mm

◆ Width: 1150mm

◆ Insulation Core: Fiber glass / Rockwool / EPS

◆ Facades: 0.4mm /0.5mm thichness galvanized color metal sheet

Flat Pack Container House Door & Window (Check for Doors & Windows details): |

◆ Door--- Light steel single open door (845*2035mm) with locker

◆ Window--- UPVC sliding window,double glass with mosquito screen &security fence

Flat Pack Container House Electrical System (Check for Electrical & Plumbing details): |

◆ Electrical wire--- 2.5mm2 for lighting system, and 4mm2 for AC units.

◆ Socket--- 10A five holes universal socket.

◆ Light--- double tube fluorescent lamp, 220V, 50-60HZ

◆ Switch--with junction box

◆ Electrical distribution box-- box + breakers + earth leakage protective device

◆ Industrial plug--- 5holes

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector