Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

AOT is the integrated supplier for all the Building materials / Construction materials, providing the ONE-STOP service for our clients.

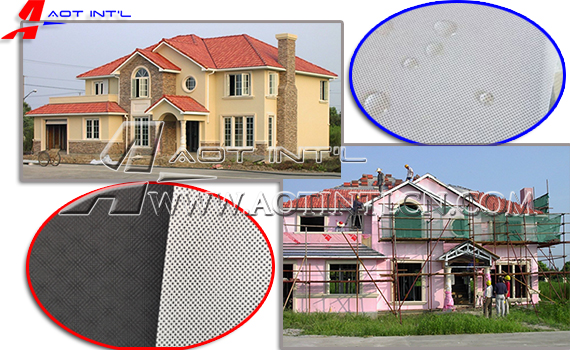

AOT Waterproof Breathable House Wrap & Roofing Underlayment

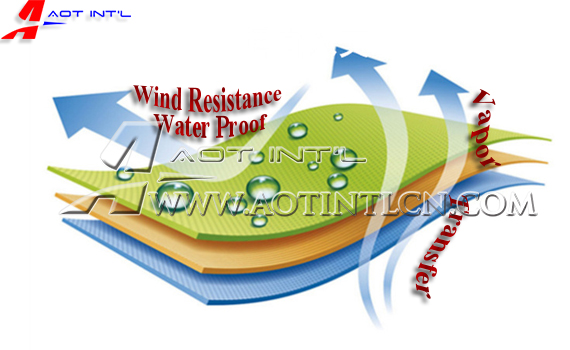

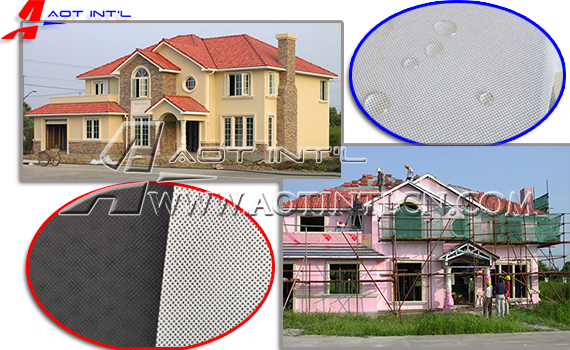

AOT House wrap is the newly designed and effective house wrap, incorporating unique material science that helps keep air and water out, while letting water vapor escape. As a result, it can contribute to improved building durability by helping to protect homes against damaging wind and rain that can penetrate the exterior cladding.

AOT Breathable house wrap can also reduce home energy bills by controlling air flow and water intrusion, which helps insulation work better, allowing the HVAC system to work more efficiently. It’s a house wrap engineered to keep homes cool in the summer, warm in the winter, and dry all year round.

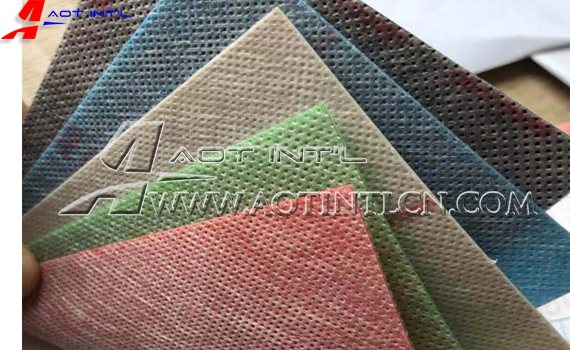

The Housewrap / Roofing Underlayment That We Supply Consist Of:

| ◆ Breathable House Wrap | ◆ Synthetic Roofing Underlayment | ◆ Waterproof Membrane |

| ◆ Vapor Transmissible House Wrap | ◆ Waterproof Breathable Housewrap | ◆ Composite Waterproofing Membrane |

| ◆ PP/PE Waterproof Membrane | ◆ Basement Waterproof Membrane | ◆ Roofing Materials Membranes |

|  |

AOT breathable membranes have excellent performance on water proof, vapor permeability and UV resistant, which are widely used in construction as roof underlayment and wall membrane. They can prevent duct, water drop from our side, but can allow air to pass through.

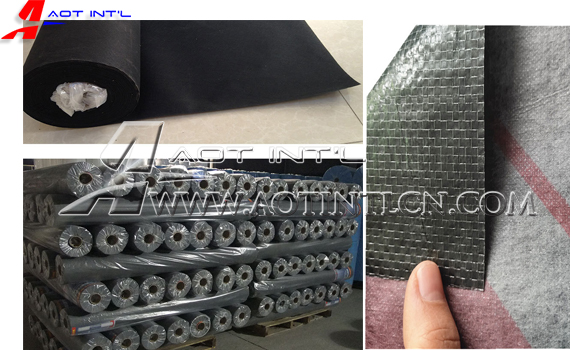

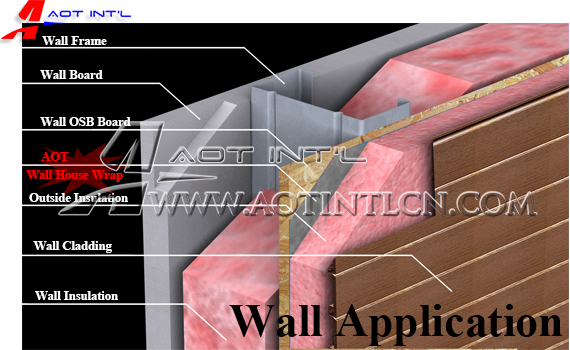

AOT Waterproof Breathable housewrap membrane is 3-layer thermo-bonded: Non-slip layer is the upper layer made by non-woven and it can be printing with over lapping lines and logos etc.

Woven fabric layer is made by high tensile strength woven fabric, mainly used as tensile strength layer.

Coating layer is used as waterproof layer.

|  |

PP non-woven fabric of top and bottom layer, Micro-porous PE film between the two layers, to form waterproof and breathable membrane, with excellent performance at water resistance (>1500/3000mm H2O) , meanwhile with particular function of high vapor permeability(1800g/3000g/m2/24h), which mainly used in construction as underlay on pitched roofs or walls.

Breathable roofing underlay positioned above the insulation layer in a warm pitched roof, or in a cold pitched roof (ventilated or unventilated). Breathable roofing underlay for use under tiles and sheeted roofs, over open rafters or on to fully boarded substrates. Breather membrane for timber frame wall construction.

AOT Housewrap / Roofing Underlayment Application |

|  |

1)Mainly used as roof underlay and house wrap protection for insulating walls.

2)Prevent rain and snow meanwhile allow water vapor to pass to the exterior. so the moisture from leakage and condensation can escape, to avoid mold and rot of fiberglass or cellulose insulation, to keep its R-value.

3)Used as windproof layer (Air barrier), reducing air leakage through the building envelope, ensuring insulation materials maintain their optimum thermal efficiency by minimizing air infiltration

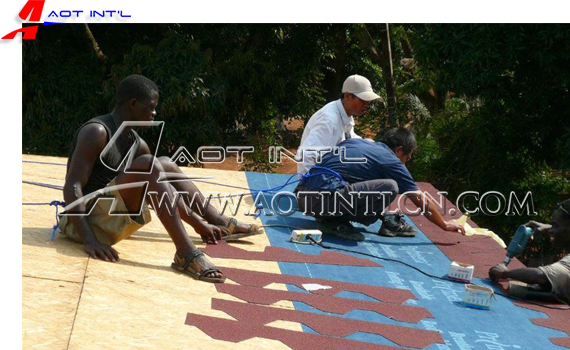

4)Used as a temporary waterproofing barrier during the construction process.

◆ AOT Breathable House Wrap Specifications |

| Items | Test Standard | Results |

| Moisture Vapor Transmission | ASTM E96 | 10-20 Perms |

| Water Proof | ASTM E96 | PASS |

| Tensile Strength | ASTM D5034 | MD-290N |

| CD-220N | ||

| Elongation (%) | ASTM D5034 | MD-55% |

| CD-55% | ||

| Resistance to UV (Month) | ASTM G154-06 | 6 Months |

| Air Permeance at 75 Pascals | ASTM E2178 | 0.002L/S/Sqm |

Products Description

-- Roll Length: 111.1ft (33.86m)

-- Roll Width: 108in. (2.74m)

-- Roll Weight: 20.5lbs (9.3kg) per roll

-- Approx. Coverage: 1,000Sqft. (92.9SQm) per roll (Excludes laps)

◆ AOT Roofing Underlayment Specifications |

| Items | Test Standard | Industry Standard | Results |

| Permeability | ASTM E96 | Null | 0.35/g/sm/day |

| (0.05 perms) | |||

| Water Transmission | ASTM D4869 | PASS | PASS |

| Tear Strength | ASTM D4533 | Null | MD-30lbf |

| CD-25lbf | |||

| Tensile Strength&Elongation (%) | ASTM D5034 | MD-50lbf Elongation 5% | MD-85lbf Elongation 22% |

| CD-30lbf Elongation 5% | CD-73lbf Elongation 22% | ||

| Burst Strength | ASTM D5034 | 35 psi (242kPa) | 130 psi (897kPa) |

| Nominal Thickness | ASTM D1777 | <21 mils (0.525mm) | 7 mils (0.18mm) |

| Warranty | Null | 30Years | |

| Temperature | 14℉ to 212℉ | -70℉ to 212℉ | |

| (-10℃ to 100℃) | (-55℃ to 100℃) |

Products Description

-- Roll Length: 286ft (87m)

-- Roll Width: 42in. (1.07m)

-- Roll Weight: 23.4lbs (10.6kg) per roll

-- Approx. Coverage: 1,000Sqft. (92.9SQm) per roll (Excludes laps)

-- UV stabilized polypropylene construction resists UV degradation up to 180days

-- UL class A fire rating

|  |

|  |