Product Details

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

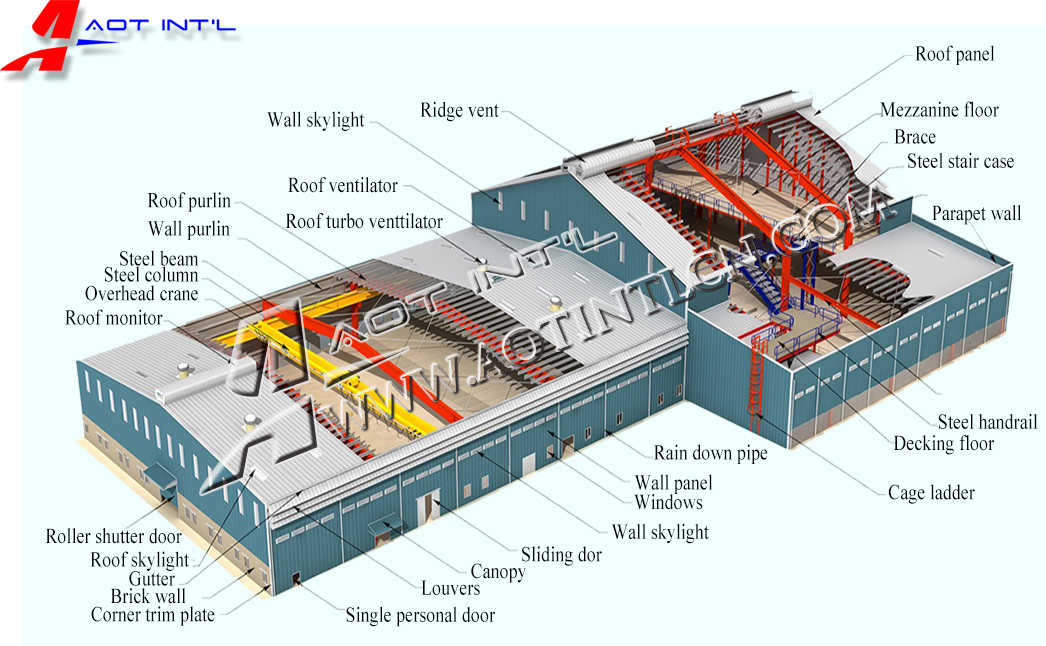

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer's requirements.

Pre-engineered steel buildings are used for diverse applications such as:

| Industry: | Commercial: | Public: |

| ★ Warehouse; | ★ High-rise building /Multi floor building; | ★ Prefabricated schools /Classrooms; |

| ★ Workshop; | ★ Shopping mall; | ★ Sports arenas & sports hall; |

| ★ Factory /Plant; | ★ Distribution centers /Showrooms; | ★ Church building; |

| ★ Cold storage building; | ★ Steel structure hotels; | ★ Steel structure hospital; |

| ★ Power plants; | ★ Car parking center; | ★ Steel frame pedestrian bridge; |

| ★ Airplane hangars & aviation hangars; | ★ Poultry farm; | ★ Garage; |

| ★ Storage shed; | ★ Agricultural building & barns; | ★ Community center; |

| ★ Self-storage building; | ★ Green house; |

Pre-Engineered Steel Structure Factory | Metal Workshop | Steel Plant: |

AOT Steel Structure Building | Pre-Engineered Factory,Workshop,Plant 3D Concept drawing

| |

| AOT Steel Structure Building | Metal Structure Workshop, Plant |

The pre-engineered steel structure building system is a building enclosure system that always includes a structural system and often includes roof and wall cladding. The general idea of the system is represented in the diagram above. The structural system consists of rigid frames that are fabricated from plate steel and “cold formed” into an “H” shape through a manufacturing process. These rigid frames consist of roof beams and columns that are field bolted together. These frames can span large distances without intermediate supporting columns. The frames are spaced at intervals between 5meter-18meter ( 15’ - 60’) and can span, column-free, up to 36meter (120’ ) across a building.

On top of and running perpendicular to these frames are roof secondary structural spanning members often referred to as purlins. They are spaced 1.2meter (4’ ) apart across the width of a building. The roofing system attaches to the purlins. The wall systems include wall secondary structural members called girts that also span from frame to frame. Girts support a wall cladding system (frequently metal panel.)

| |

| AOT Steel Structure Building | Steel Structure Factory|Metal Workshop,Plant |

Design

A pre-engineered metal building, also known as a pre-manufactured or pre-fabricated metal building, is designed to specification at the manufacturer. There are numerous designs available, all of which can be customized as needed.

Specialized software and other design tools are readily available.

Materials

Since these buildings are not created until the design is complete, the members and panels are created as needed, minimizing the amount of steel required and resulting in a lighter-weight building. Every piece is sourced from the manufacturer.

Each piece is precision rolled, cut, punched, and marked to make assembly as easy as possible once the kit reaches the jobsite. Everything is included in the kit: members, panels, and fasteners, which have all been tested for fit before shipping.

Foundation

A pre-engineered building has the advantage of a known weight, simplifying foundation design. Also, since pre-engineered buildings use customized members, less steel is needed to create them and results in a lighter building that needs a less complex or heavy foundation.

Framing

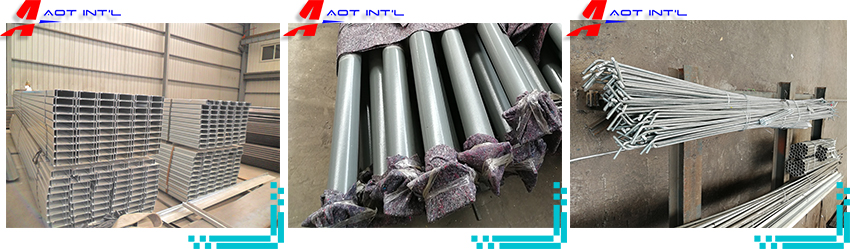

Pre-engineered primary and secondary framing members are custom-made for each building designed. Instead of standard T-sections, tapered members that are sturdy yet light-weight can be used in the primary frame. Secondary members are steel Z and C shapes; all girts and purlins are lightweight steel as well.

No field cutting is needed to create frame members to fit; they simply bolt together as designed as punched in the factory.

Expansion and repair

Pre-engineered steel buildings are eminently expandable and easily customized to new uses. New sections are readily bolted onto any side or added to the top of an existing structure.

Original, engineer-stamped documents assist future redesign work and streamline the permitting process. If a section of the building is damaged, repairs can be performed easily, often using replacement parts from the original manufacturer.

Durability

Pre-engineered steel buildings have come a long way from the simple sheds you see along the side of the road. A multi-story or wide-span building can be pre-engineered as can anything in between, built to last for decades and able to be disassembled and moved if needed.

Every pre-engineered building is designed to meet the local building standards and requirements. Specialized connections and framing are designed in for seismically active regions or any other special environmental concern.

| |

| AOT Steel Structure Building | Steel Structure Factory|Metal Workshop,Plant |

The best applications for the pre-engineered metal building system include industrial applications such as complex industrial facilities, workshops, factory, plant, warehouses and distribution centers. The system is also used in retail stores, shopping centers, motels, auto dealerships, office complexes, airplane hangars, sports and entertainment arenas as well as schools, libraries, churches, medical facilities and government buildings.

Pre Engineered Factory,Workshop,Plant Technical Specifications |

| Main steel structure | Q235, Q345 steel, Welded type H section. Box section frames |

| Surface Treatment | Sa2.5 grade shot blasting, Alkyd painting, or Epoxy zinc-rich painting, or Galvanization according customers' requirements |

| Purlins | C section, Z section profiles, Electro-galvanized, 40g/m2, 60g/m2, 90g/m2, 275g/m2, according customers' requirements |

| Bracing system | Including Cross brace, Column brace, Knee brace, Batter brace, Tie bar etc. |

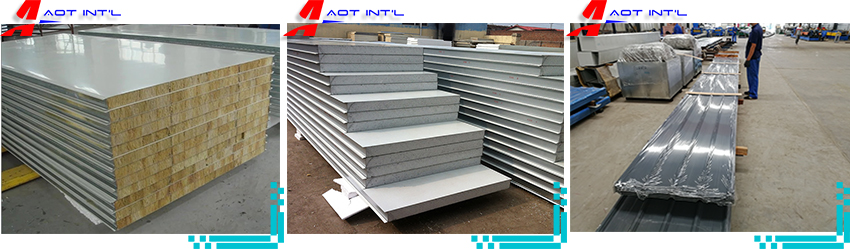

| Wall & Roof cladding system | Single corrugated galvanized metal sheet, or Insulated sandwich panels, such as Rockwool, Fiberglass, EPS, PU etc. |

| Doors | Electric Roller shutter door, or Sliding door, or Singe open / Double open door |

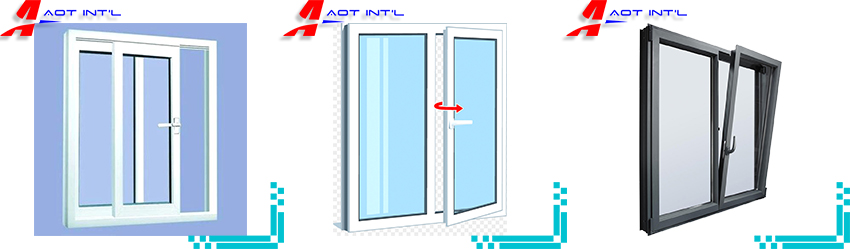

| Windows | UPVC / Aluminum windows |

| Rainspout system | Galvanized gutter, UPVC down pipes |

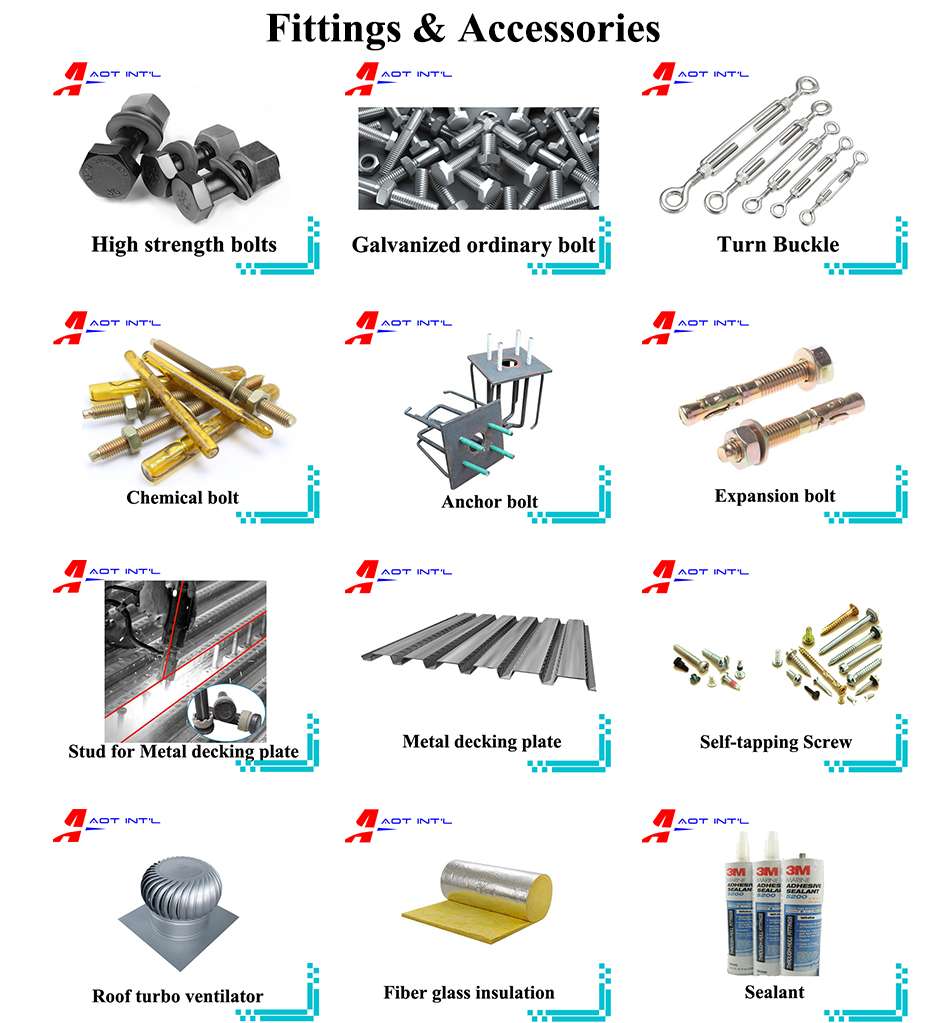

| Fittings & Accessories | Anchor bolt, High-strength bolt, Screw, Trim plate, Sealing glue etc. |

Main steel structure: Steel frames, H type, I type, Box type |

Brace: C section / Z section purlin, Round steel rod, L steel brace |

Wall & Roof cladding system: Sandwich panels, Galvanized color steel sheet (Check for more details) |

Industrial door: Roller shutter door, Sliding door, Steel door (Check more details) |

Windows: Aluminum window, PVC window, Sliding window |

Fittings & Accessories: Anchor bolt, High strength bolt, Turn buckle, Metal decking plate, Stud, Sealant etc. |

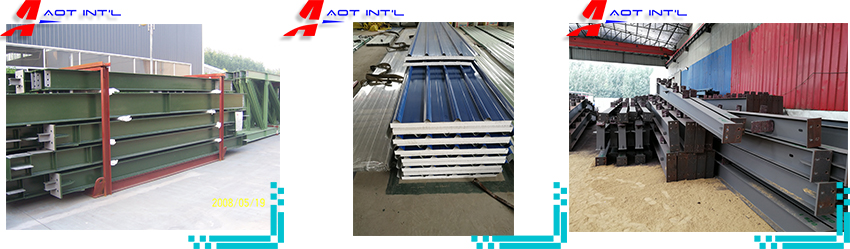

Package & Loading |

Quality Assurance and Control |

AOT, Quality assurance program endeavors management commitment to seed quality in all phases of its activities. The commitment begins from approaching inquiries, meeting the requested specifications, handling project documents, in-process quality inspections, to meet the delivery schedule and till the end products are erected satisfactorily. AOT quality assurance program comprising:

● Raw materials traceability

● Fabrication inspection, such as Cutting, Drilling, Beveling, Welding operation, Fit-up, Rust cleaning, Painting inspection, Dimension accuracy inspection

● Package inspection, to protect the materials during transportation, further more to meet the loading requirements into containers

● Documents collection, such as detailed packing list, installation drawings

Equipment: |

● Coating thickness gauge

● Digital profile gauge

● Micrometer caliper

● Ultrasonic flaw detector