Pre-Engineered Steel Buildings Description Part 01--Framing System

AOT, a brand of PEBs, Prefabricated house and Modular container house, is Trusted & Tested.

Pre-engineered steel structure building is steel structure built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer’s requirements.

The entire primary members and secondary members are designed and fully fabricated including cut-to-length, punching, drilling, welding and preforming in the factory before shipped to the site for erection.

At the site, all components are assembled and jointed via nut & bolt connections; thereby reducing the costs and assembly times.

Primary Framing

Welded type H section beam, Box beam or I beam construction for optimum strength. Material is Q345 (Low-alloy & High strength structural steel Q345 ‘GB/T 1591-94 standard’) or Q235 (Carbon structural steel Q235 ‘GB 700--88 standards’), yield strength is 345MPa, Tensile strength is 470~630. By using a higher yield strength material, a smaller web can be utilized which means a space saving design. Frames are single bead; continuous submerged arc welded by automatic welding machines (this helps insure quality control). The surface treatment will be Sa2.5 grade shot blasting, Alkyd painting, or Epoxy zinc-rich painting, or Galvanization according customers’ requirements.

Secondary Framing

Girts (in sidewall) & Purlins (in roof) are cold rolled C section, Z section profiles, Electro-galvanized, 40g/m2, 60g/m2, 90g/m2, 275g/m2, according customers’ requirements. Bypass girt system overlaps at sidewall columns forming a continuous “beam” for extra strength. Purlins are top-mounted on the rafter. Maximum purlin spacing is 1.5meter on center. Eave Strut is a cold-formed C-Section that is rolled for the appropriate roof pitch, to help insure weather tightness at the eave. Sheeting angle is a continuous sheeting angle supplied for the attachment of the sheeting at the rake of the building for ease of installation. Base angle is a continuous angle, supplied for the attachment of the base of the sheeting to the concrete. It is attached to the concrete with ram-sets or equivalent anchors by others. Bracing diagonal rod or cable bracing may be supplied for roof and walls to remove longitudinal load from the structure. Angle Flange Bracing is provided for the connection of the rigid frame to the purlins and girts. This ensures that allowable compression levels are adequate for any combination of loadings. Purlin bridging angles may be provided at each mid-bay to assure consistent purlin spacing and stiffening.

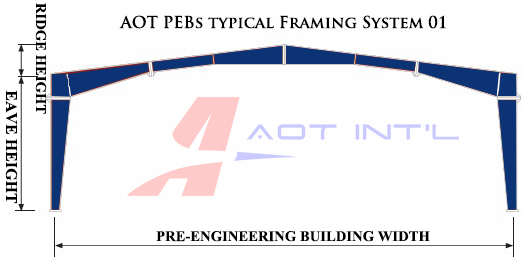

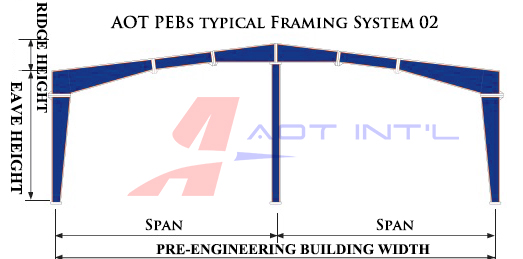

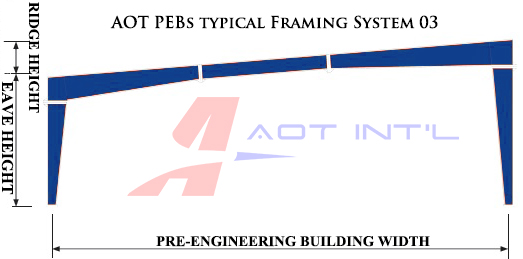

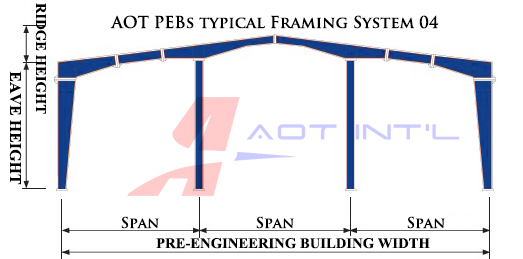

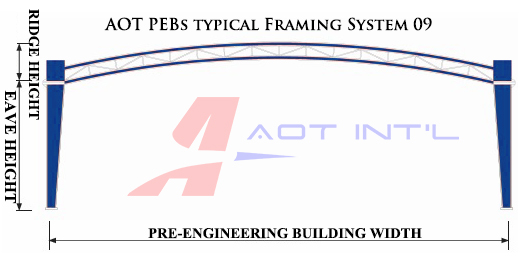

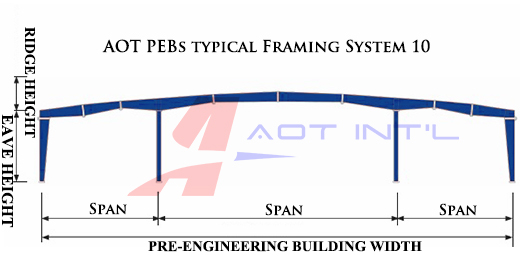

AOT provides kinds of typical framing system. Each one has its own advantages and suited for different applications.

|

|

| PEBs Typical Framing System 01, Max. Width=36m | PEBs Typical Framing System 02, Max. Width=100m |

|

|

| PEBs Typical Framing System 03, Max. Width=30m | PEBs Typical Framing System 04, Max. Width=150m |

|

|

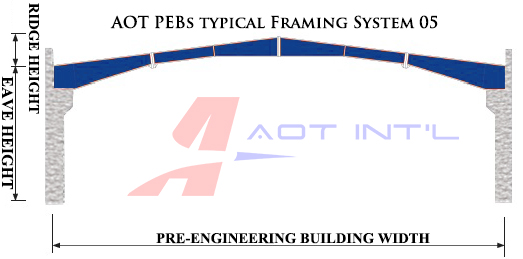

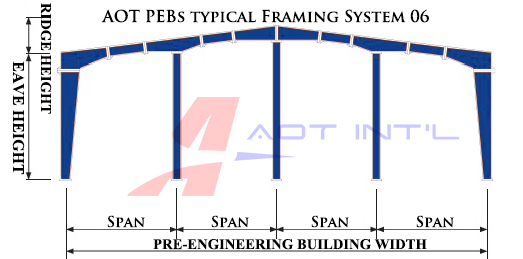

| PEBs Typical Framing System 05, Max. Width=50m | PEBs Typical Framing System 06, Max. Width=200m |

|

|

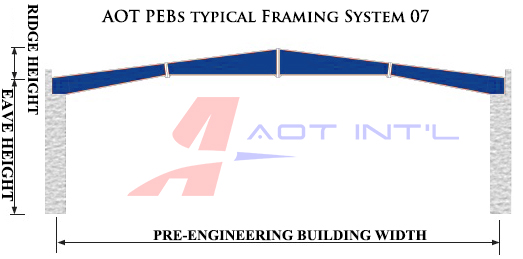

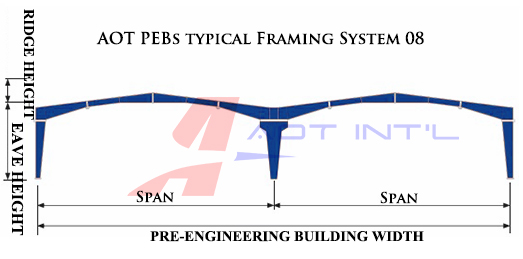

| PEBs Typical Framing System 07, Max. Width=60m | PEBs Typical Framing System 08, Max. Width=100m |

|

|

| PEBs Typical Framing System 09, Max. Width=100m | PEBs Typical Framing System 010, Max. Width=150m |